-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

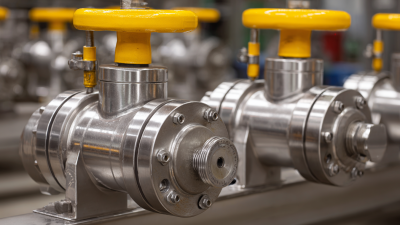

In the realm of industrial applications, the choice of valves plays a crucial role in ensuring efficiency, reliability, and safety in fluid control systems. Among the various types of valves available, Duplex Ball Valves have emerged as a preferred option for many industries due to their unique configuration and performance benefits. These valves, constructed with two ball units, offer a streamlined solution that enhances the flow characteristics while minimizing the risk of leakage.

Duplex Ball Valves are particularly advantageous in settings that require high-pressure handling and the ability to switch between processes without interrupting service. Their robust design allows for greater durability and resistance to corrosion, making them suitable for challenging environments, including chemical processing and oil and gas applications. This article delves into the multifaceted advantages of Duplex Ball Valves, exploring how they elevate efficiency and operational integrity in an array of industrial contexts. By understanding their benefits, engineers and decision-makers can make more informed choices when selecting components for their fluid management systems.

Duplex ball valves offer significant advantages in streamlined fluid control, especially in industrial applications requiring reliability and efficiency. Their robust design and construction allow for effective handling of various fluids, including corrosive and abrasive materials. This capability is critical in industries such as oil and gas, chemical processing, and wastewater treatment, where the integrity of the fluid flow system is paramount. Duplex stainless steel materials ensure enhanced durability and resistance to extreme operating conditions, reducing the risk of leaks and failures.

Moreover, duplex ball valves facilitate quick and easy operation, which is essential for maintaining operational efficiency. Their quarter-turn mechanism allows for rapid opening and closing, minimizing downtime during maintenance or emergency situations. Additionally, these valves provide a tight seal, preventing backflow and ensuring that the fluid control remains predictable and efficient. The combination of strength, corrosion resistance, and operational effectiveness makes duplex ball valves a superior choice for businesses aiming to optimize their fluid control processes while ensuring safety and reliability in demanding environments.

The chart above illustrates the key advantages of duplex ball valves in various industrial applications, highlighting their performance metrics in critical areas such as corrosion resistance, strength, cost efficiency, durability, and maintenance requirements.

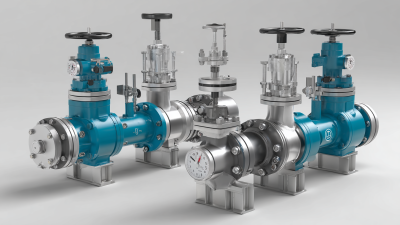

Duplex ball valves are increasingly favored in industrial applications due to their enhanced durability and longevity when compared to traditional valves. Constructed from high-quality materials such as duplex stainless steel, these valves exhibit superior resistance to corrosion and wear, making them ideal for harsh operating environments. This resistance significantly extends their operational lifespan, reducing the frequency of replacements and maintenance interventions, which can be costly and time-consuming in industrial settings.

Moreover, the design of duplex ball valves contributes to their robustness. With fewer components than traditional valves, they minimize the risk of mechanical failure. This simplified structure not only enhances performance reliability but also ensures higher flow rates and reduced turbulence, which can benefit system efficiency. By investing in duplex ball valves, industries can achieve greater operational efficiency while also enjoying the long-term economic benefits of reduced downtime and maintenance costs.

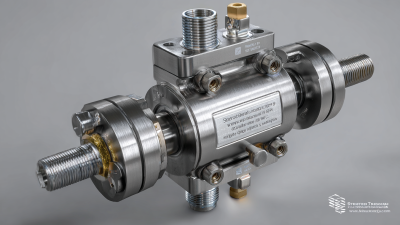

Duplex ball valves are increasingly recognized for their enhanced leak prevention capabilities, significantly improving safety in industrial settings. A recent report by the Flow Control Engineering Association indicates that nearly 30% of industrial accidents are linked to valve failures, underlining the importance of reliable containment systems. Duplex ball valves, designed with two independent chambers, offer robust sealing mechanisms that minimize the risk of leakages, thus protecting both personnel and the environment.

In addition to their leak-proof design, duplex ball valves contribute to safety by facilitating easier maintenance and operational efficiency. According to the Valve Manufacturers Association, industries that implement duplex systems report a 20% increase in maintenance efficiency, as these valves can be serviced without disrupting the flow in adjacent systems. This feature not only reduces downtime but also mitigates risks associated with fluid disruption, making duplex ball valves a superior choice for industries where safety and reliability are paramount.

Duplex ball valves have gained attention in industrial applications primarily for their economic advantages over time. According to a report from MarketsandMarkets, the global ball valve market is expected to reach approximately $8 billion by 2023, underscoring the growing adoption of this technology across various industries. The cost-effectiveness of duplex ball valves can be attributed to their superior durability and resistance to corrosion. This results in longer service life, which reduces the frequency and cost of replacements. The alloy composition of duplex stainless steels, which have yield strengths approximately twice that of standard austenitic stainless steels, contributes significantly to their longevity under harsh operating conditions.

Moreover, a study published by the International Journal of Pressure Vessels and Piping indicated that duplex ball valves can operate efficiently at higher pressures, making them ideal for oil and gas applications. This operational efficiency translates to lower operational costs, as the energy consumption is minimized. Furthermore, the maintenance costs can be up to 30% lower over the lifespan of duplex ball valves compared to conventional options, according to a recent analysis by the Valve Manufacturer’s Association. These financial advantages reaffirm the rationale for industries to invest in duplex ball valves, ensuring not only enhanced performance but also substantial cost savings in the long run.

Duplex ball valves have gained notable recognition for their versatility across various industrial applications. Their unique design allows for excellent flow control and efficient operation, making them suitable for a wide range of industries, including oil and gas, water treatment, and chemical manufacturing. The inherent simplicity of their operation provides reliable performance even under extreme conditions, which is essential for critical industrial processes.

Tips: When considering duplex ball valves for your applications, assess the specific fluid dynamics involved and ensure compatibility with your system's material requirements. It’s also beneficial to evaluate the maintenance needs, as some configurations may offer easier access for repairs and replacements.

Moreover, advancements in valve technology reflect a broader trend towards innovative solutions in industrial settings. Just as the latest developments in imaging and power supply technologies emphasize customization and efficiency, duplex ball valves are being integrated into systems that require seamless interaction with modern automated processes, enhancing overall operational productivity.

Tips: Always prioritize selecting valves that not only meet current industry standards but also offer adaptability for future upgrades. This foresight can lead to long-term cost savings and improved system reliability in the fast-evolving industrial landscape.