-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

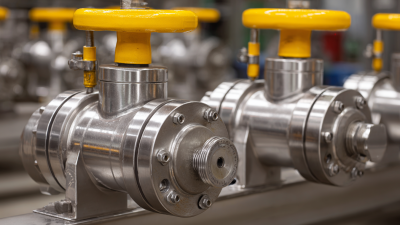

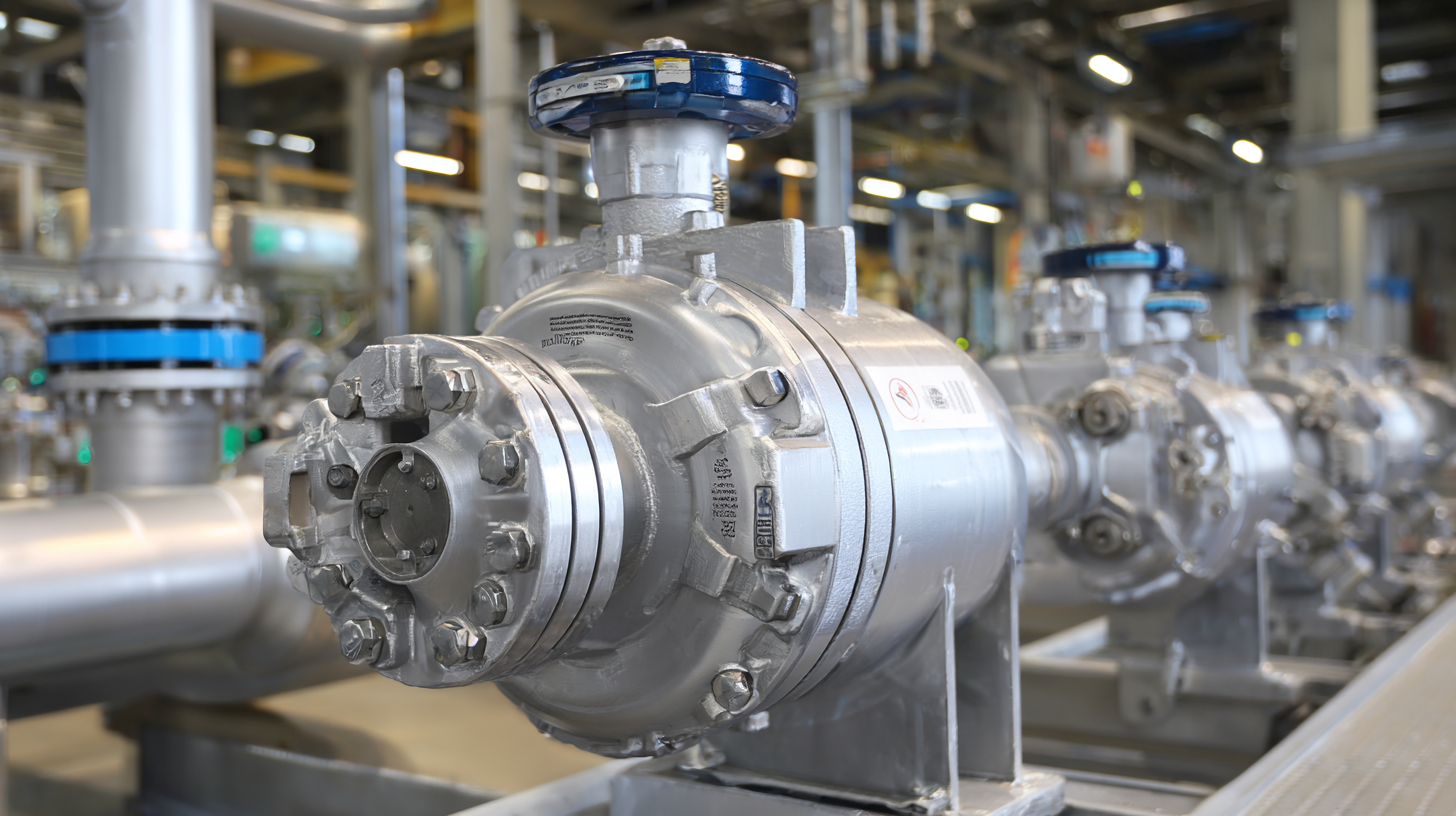

In the realm of industrial applications, the choice of valves plays a crucial role in ensuring efficiency, reliability, and performance. Among the various types of valves available, the Ball Valve Wafer Type stands out as a highly effective solution for fluid control. This innovative valve design offers a multitude of advantages that are particularly beneficial in industrial settings, where precision and durability are paramount. As industries strive for operational excellence, understanding the top benefits of utilizing Ball Valve Wafer Type is essential for making informed decisions.

One of the most notable advantages of the Ball Valve Wafer Type is its compact design, allowing for easy installation and reduced space requirements. This feature is particularly advantageous in environments where space is limited. Furthermore, the wafer-style configuration enhances the valve's ability to handle high pressures and temperatures, making it suitable for a variety of demanding applications. As we explore the top ten benefits of using this type of valve, it becomes evident that its integration can lead to improved efficiency and significant cost savings, establishing the Ball Valve Wafer Type as an indispensable component in modern industrial systems.

Wafer type ball valves are increasingly favored in industrial applications due to their compact design, which plays a significant role in space optimization. These valves are engineered as thin, flat discs that can easily fit between flanges, minimizing the physical footprint required for installation. This design feature is particularly advantageous in environments with limited space, such as within pipelines or tightly packed machinery. By using wafer type ball valves, operators can efficiently manage flow control without sacrificing valuable real estate, thus enhancing overall productivity.

Moreover, the lightweight nature of wafer type ball valves reduces the burden on supporting structures, making them ideal for industries where equipment weight can be a critical consideration. The ability to install these valves in confined spaces not only simplifies maintenance and replacement processes but also allows for greater flexibility in system design. Consequently, industrial facilities can realize design efficiencies, streamline their processes, and reduce installation costs, all of which contribute to enhanced operational efficacy.

| Benefit | Description | Impact on Application |

|---|---|---|

| Compact Design | Wafer type ball valves are designed to occupy less space compared to standard valves. | Ideal for installations with limited space. |

| Lightweight | These valves are lighter than traditional valve types, facilitating easier handling. | Reduces installation costs and time. |

| Cost-Effective | Lower material usage leads to overall cost savings. | Enhanced economic efficiency in projects. |

| Versatility | Suitable for various fluids and gases, accommodating diverse applications. | Allows for a broader range of use in different industries. |

| Easy Installation | Simplifies the installation process due to its design. | Minimizes operational downtime during setup. |

| Low Maintenance | Requires less frequent servicing compared to other valve types. | Decreases operational costs in maintenance. |

| Reliable Performance | Offers consistent functionality across various conditions. | Ensures safety and reliability in critical operations. |

| Quick Operation | Fast open and close functionality allows for immediate control. | Enhances process efficiency. |

| Excellent Flow Control | Provides superior flow characteristics, minimizing turbulence. | Promotes better system performance. |

| Corrosion Resistance | Manufactured with materials that resist corrosion over time. | Enhances longevity and reliability in harsh environments. |

Wafer type ball valves have garnered attention in industrial applications primarily due to their ability to enhance flow efficiency and reduce pressure drop. According to a report from the Flow Control Association, implementing wafer type ball valves can lead to a flow coefficient (Cv) increase of up to 20% compared to traditional valve designs. This efficiency directly results in minimal energy losses in fluid transport systems, making them a preferred choice for many industries such as petrochemical, water treatment, and HVAC.

Moreover, the streamlined design of wafer type ball valves minimizes turbulence and friction, which are critical factors in reducing pressure drops across the system. A study from the International Journal of Fluid Mechanics indicates that pressure drops can be reduced by approximately 30%, leading to lower operational costs and improved system reliability. These valves are particularly beneficial in tight spaces where traditional valves may not fit, allowing for better integration into existing piping systems without sacrificing performance. As industries continue to prioritize efficiency, the adoption of wafer type ball valves is expected to rise significantly, transforming how fluid systems operate.

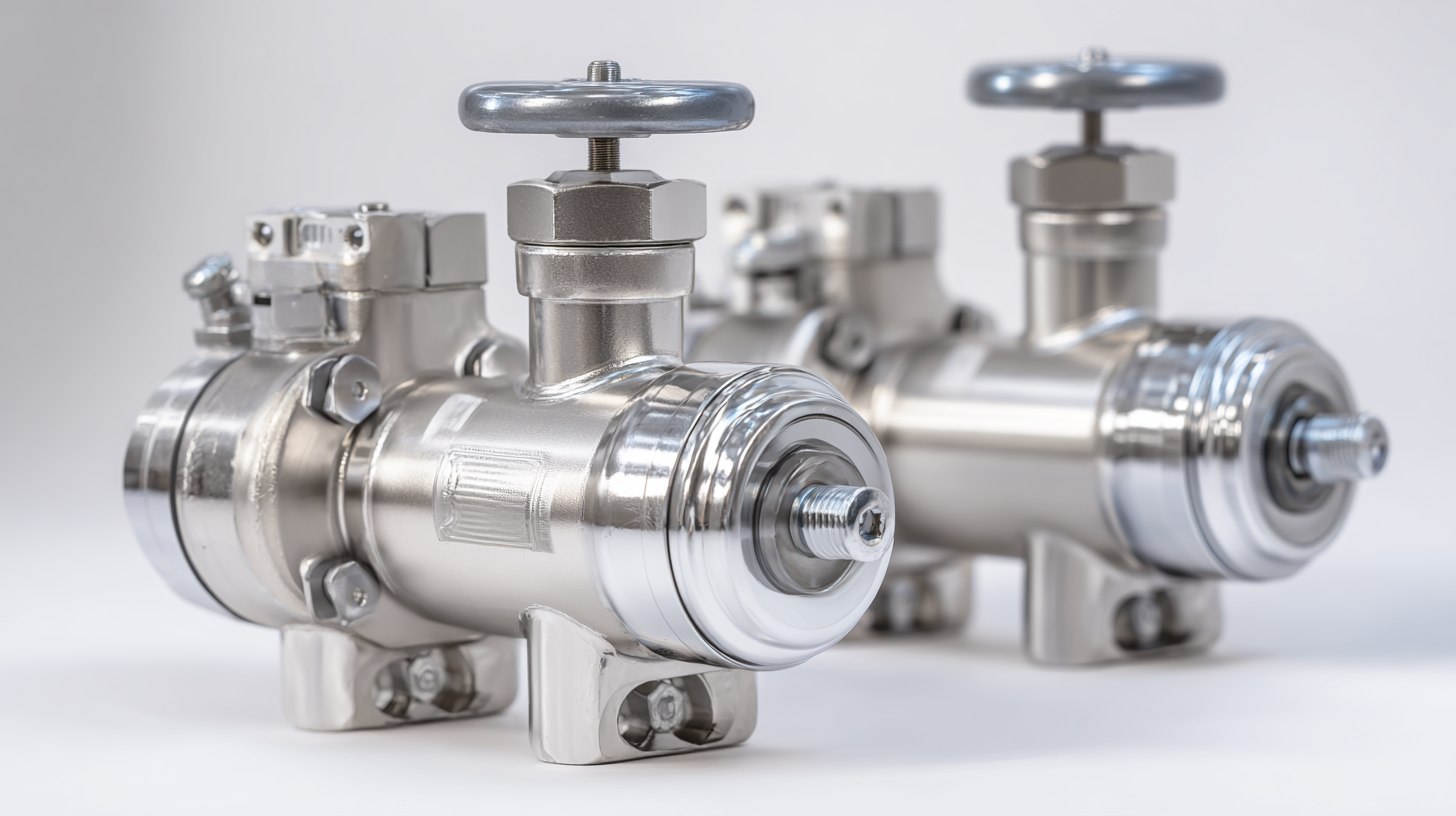

Wafer type ball valves are increasingly favored in industrial applications due to their exceptional durability and reliability. Constructed with high-quality materials, these valves can withstand extreme pressures and temperatures, making them ideal for various demanding environments. Their compact design allows for easy installation between flanges, reducing the need for additional space and supporting infrastructure. This feature not only enhances the overall efficiency of the system but also contributes to their long-term performance by minimizing stress on connected components.

Wafer type ball valves are increasingly favored in industrial applications due to their exceptional durability and reliability. Constructed with high-quality materials, these valves can withstand extreme pressures and temperatures, making them ideal for various demanding environments. Their compact design allows for easy installation between flanges, reducing the need for additional space and supporting infrastructure. This feature not only enhances the overall efficiency of the system but also contributes to their long-term performance by minimizing stress on connected components.

Moreover, the reliability of wafer type ball valves is evident in their low maintenance requirements. Their simple design limits the number of components that could fail over time, ensuring that they operate effectively for extended periods. Many industries have reported reduced downtime and maintenance costs when incorporating these valves into their processes. By consistently delivering reliable performance, wafer type ball valves help businesses maintain productivity and operational efficiency while enhancing the longevity of their piping systems.

Wafer type ball valves are gaining traction in industrial applications not only for their performance but also for their cost-effectiveness in maintenance and installation. Unlike traditional valve designs, wafer type ball valves feature a compact, lightweight design that allows for easier installation between flanges, reducing labor time and associated costs. This simplicity in installation makes them particularly attractive for projects with tight deadlines and limited budgets.

In terms of maintenance, wafer type ball valves require less frequent servicing compared to other valve types, primarily due to their reliable sealing capabilities and lower susceptibility to wear and tear. This durability translates to fewer interruptions for repairs or replacements, ultimately leading to significant savings over the lifespan of the equipment. Additionally, their design minimizes the risk of leaks, further enhancing their cost-effectiveness by lowering the chances of costly downtime or product loss, making them an ideal choice for industries looking to optimize their operational expenses.

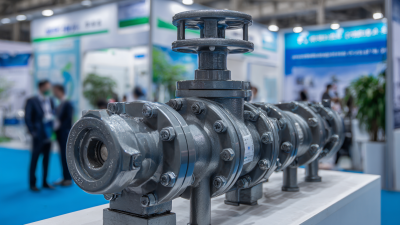

Wafer type ball valves have gained significant popularity across various industrial applications due to their unmatched versatility. These valves are designed for easy installation between flanges, making them ideal for a wide range of pipeline systems. Their compact construction minimizes the need for additional support structures, allowing for easier integration within existing layouts. This flexibility is particularly beneficial in settings where space is a constraint, such as in chemical processing, water treatment, and power generation facilities.

In addition to their space-saving design, wafer type ball valves offer remarkable operational efficiency. They provide full flow with minimal pressure drop, which is crucial for systems requiring precise flow control. Their robust construction ensures durability and resistance to wear and tear, making them suitable for handling various media, including corrosive substances and high-pressure applications. As industries continue to seek optimal solutions to enhance productivity and reduce costs, the versatility of wafer type ball valves positions them as a reliable choice for modern industrial operations.