-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

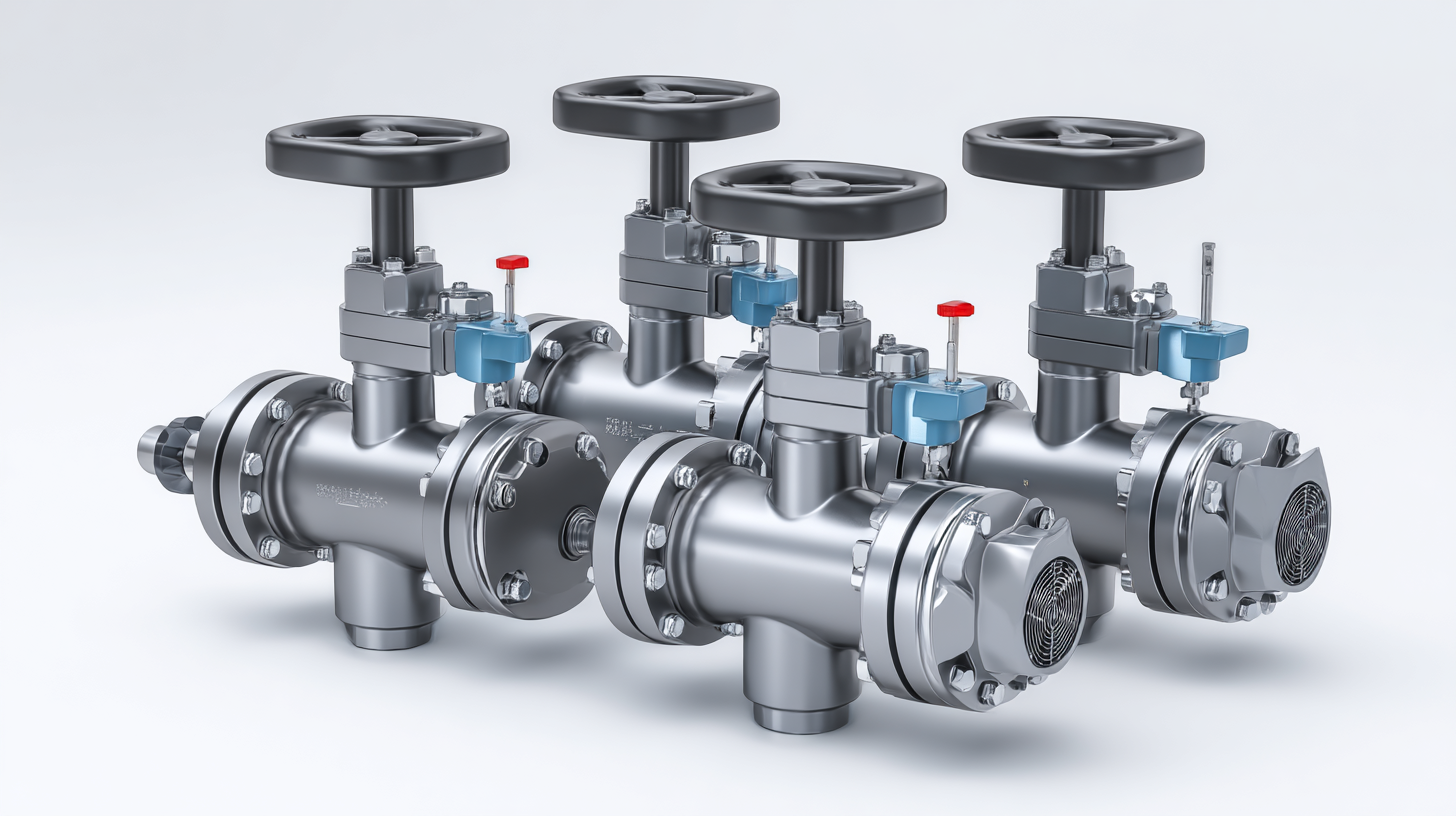

In the realm of industrial applications, the efficiency of fluid control systems is paramount. Among the various components that facilitate optimal flow management, ball valves have gained significant recognition for their superior performance and reliability. According to a recent report by the Global Market Insights, the ball valve market is projected to reach USD 9.1 billion by 2027, with an anticipated CAGR of 4.9%. This growth underscores the demand for high-quality ball valves that can maintain system integrity while ensuring cost efficiency.

Choosing the right ball valves is essential for maximizing operational effectiveness. Their design allows for minimal pressure drop and excellent flow characteristics, making them ideal for processes ranging from oil and gas to water treatment. A study published in the Journal of Industrial Valve Research highlighted that using high-performance ball valves can lead to a reduction in energy usage by up to 30%, showcasing their critical role in promoting sustainability within industrial settings. As industries increasingly adopt advanced technologies, the selection of top-rated ball valves becomes crucial for achieving both immediate and long-term operational goals.

This guide will explore the 2025 top 5 ball valves that stand out in terms of performance ratings and cost efficiency, aiding professionals in making informed decisions for their specific applications.

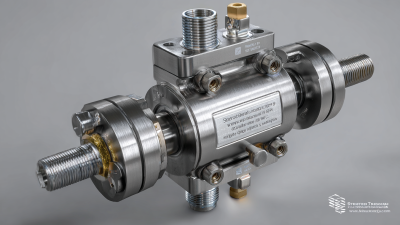

When selecting ball valves for industrial applications, several key factors significantly influence their performance. One of the primary considerations is the valve material, which must be compatible with the fluid being controlled. Common materials include stainless steel, brass, and PVC, each offering distinct advantages regarding corrosion resistance and pressure handling capabilities. The choice of material not only affects durability but also impacts the overall flow efficiency, as some materials provide smoother passageways that reduce turbulence and pressure drops.

Another critical factor is the valve design, particularly the ball and seat configuration. A well-engineered design ensures tight sealing and minimizes leakage, which is crucial in maintaining optimal flow rates. Additionally, the size and port configuration of the valve play a vital role in determining its flow characteristics. A full-port design typically offers less resistance and allows for maximum flow, making it a preferred choice in many industrial applications. Finally, the valve's actuation method—manual, pneumatic, or electric—must align with operational needs, ensuring reliable and responsive control over varied pressures and flow rates.

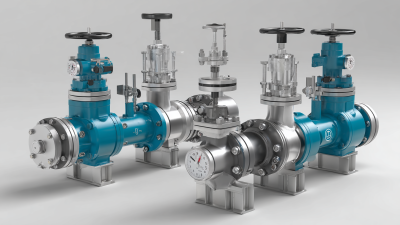

In the realm of industrial applications, ball valves are favored for their ability to provide precise flow control. A comparative analysis of different ball valve types reveals distinct advantages and limitations that impact their performance in various settings. For instance, floating ball valves are excellent for low-pressure systems due to their simple design and cost-effectiveness, with average performance efficiency rates around 90% under optimal conditions. However, they are not ideal for high-pressure applications where a trunnion-mounted ball valve would be a better choice, boasting better stability and a performance efficiency exceeding 95%.

Additionally, the material composition of ball valves plays a critical role in their durability and cost efficiency. Stainless steel ball valves, while initially more expensive, often have a lifespan that outstrips that of PVC or cast iron alternatives, translating to lower long-term maintenance costs. Industry reports indicate that stainless steel, despite being 20-30% costlier upfront, can provide up to 50% greater operational lifespan in corrosive environments. Understanding these nuances allows engineers to make informed decisions that align with both operational needs and budgetary constraints, ensuring optimal flow control across industrial applications.

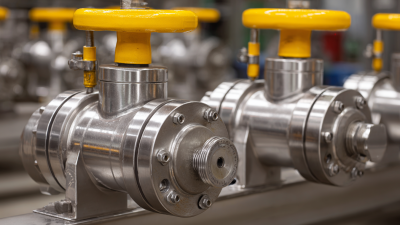

In the realm of industrial applications, selecting the right ball valve is crucial for optimizing flow control while maintaining cost efficiency. According to a report by MarketsandMarkets, the global ball valve market is projected to reach USD 15.1 billion by 2025, growing at a CAGR of 5.2%. This highlights the increasing demand for high-performance ball valves that not only meet operational requirements but also offer significant ROI.

When evaluating the cost-benefit of high-performance ball valves, factors such as materials, design, and maintenance needs play pivotal roles. A study by Grand View Research indicates that the use of advanced materials in ball valves enhances durability and reduces downtime, leading to lower long-term operational costs. For instance, stainless steel ball valves, while initially more expensive, exhibit superior performance and longevity, ultimately resulting in cost savings over their lifecycle. This strategic investment in quality valves translates to improved reliability and efficiency in industrial processes, justifying their upfront costs.

Moreover, the performance ratings of these valves can significantly influence operational efficiency. A report from Flow Control magazine emphasizes that high-performance ball valves can maintain tighter seals and better flow rates, which are critical in industries like oil and gas, water treatment, and chemical processing. By implementing these high-performance solutions, companies can not only enhance their operational capabilities but also achieve better compliance with industry standards, further supporting the case for their economic viability.

When selecting ball valves for industrial applications, adhering to industry standards and certifications is crucial for ensuring reliability and performance. Various organizations, such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO), provide guidelines that help manufacturers and users determine the quality and safety of ball valves. Certification marks from these organizations often indicate that a valve has been rigorously tested for durability, pressure resistance, and overall performance, making it easier for engineers to choose reliable fixtures for their systems.

Moreover, compliance with standards such as the American Society of Mechanical Engineers (ASME) and the American Petroleum Institute (API) not only guarantees that the valves meet the necessary operational requirements but also facilitates maintenance and replacement procedures. These certifications assure consumers that the product can withstand the challenges of high-pressure and high-temperature environments, crucial in industries like oil and gas, chemical processing, and water treatment. By focusing on these industry benchmarks, operators can confidently make informed choices, enhancing flow control efficiencies while minimizing maintenance costs.

| Valve Type | Material | Size (inches) | Pressure Rating (PSI) | Temperature Range (°F) | Certification | Estimated Cost ($) |

|---|---|---|---|---|---|---|

| Full Port | Stainless Steel | 1 | 1500 | -50 to 400 | API 607 | 75 |

| Trunnion Mounted | Carbon Steel | 2 | 2000 | -20 to 350 | ISO 9001 | 120 |

| Split Body | Brass | 1.5 | 600 | -10 to 250 | CE | 50 |

| V-Port | PVC | 2 | 150 | -10 to 140 | NSF | 30 |

| Electric Actuated | Stainless Steel | 3 | 1000 | -20 to 300 | UL | 150 |

| Caged Ball | Ductile Iron | 4 | 3000 | -40 to 400 | AWWA | 200 |

| Floating Ball | Aluminum | 1 | 600 | -20 to 250 | FM | 55 |

| High Pressure | Nickel Alloy | 0.75 | 5000 | -50 to 600 | ASME | 350 |

| Low Flow | Plastic | 0.5 | 150 | -10 to 180 | RoHS | 20 |

| Multi-Port | Bronze | 2.5 | 800 | -10 to 300 | BPE | 130 |

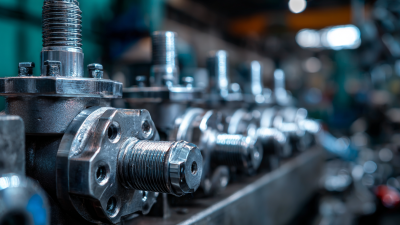

Emerging technologies are revolutionizing the ball valve industry, significantly enhancing efficiency and flow control in various industrial applications. According to a report by Research and Markets, the global ball valve market is projected to grow at a compound annual growth rate (CAGR) of 5.1% from 2022 to 2027, driven by advancements in materials and automation. Innovations such as advanced actuation systems and smart technologies enable real-time monitoring and control, ensuring optimal performance and reduced downtime. This transformation allows industries to adapt to increasingly demanding environmental regulations and operational efficiencies.

Furthermore, the introduction of new materials, such as high-performance polymers and composite materials, is improving the durability and reliability of ball valves under extreme conditions. A study published in the Journal of Industrial Technology indicates that these materials can withstand aggressive chemicals and high temperatures, extending the service life of ball valves by up to 30%. Additionally, the integration of IoT (Internet of Things) technology allows for predictive maintenance and automated systems, which have shown to reduce operational costs by approximately 20%, as per a report by McKinsey & Company. This synergy between technological innovation and robust materials design underscores the importance of staying abreast of emerging trends to ensure optimal flow control in industrial applications.