-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In various industrial applications, the efficiency and reliability of fluid control systems are paramount, making the selection of the right components crucial. Manual ball valves, known for their robust performance and simple operation, play an instrumental role in regulating fluid flow across numerous sectors, including oil and gas, chemical processing, and water management. According to a report by MarketsandMarkets, the global ball valve market is projected to grow from USD 11.69 billion in 2020 to USD 15.61 billion by 2025, highlighting a significant demand for effective flow control solutions. This growth underscores the importance of selecting high-quality manual ball valves, which can ensure optimal performance and longevity in demanding environments. In this blog, we will explore the seven best manual ball valves designed to enhance operational efficiency and reliability in your industry.

When selecting manual ball valves for industrial applications, several key features should be prioritized to ensure optimal performance. One of the most critical factors is the valve material, as it directly affects durability and resistance to corrosion. According to a report by Research and Markets, the global demand for corrosion-resistant materials in valve applications is expected to grow at a CAGR of 6.3% from 2021 to 2026. Stainless steel and brass are highly recommended for applications involving aggressive fluids, making them ideal choices for various industries.

Another important feature to consider is the valve size and connection type, which should match the specific needs of the piping system. A study published by MarketsandMarkets indicates that the market for manual ball valves is projected to reach USD 9.7 billion by 2025, driven largely by the increasing need for efficient fluid control in industries such as oil and gas, water treatment, and chemical processing. Ensuring that the valve supports the right flow rates and pressure ratings can significantly enhance system performance and longevity. Therefore, attention to size, functionality, and connection compatibility is essential for achieving optimal valve performance in any operational setting.

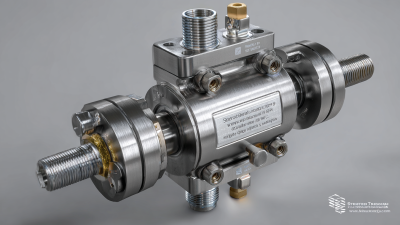

When selecting manual ball valves for industrial applications, understanding the materials used is crucial for optimal performance and longevity. The choice of material impacts not only the valve’s durability but also its ability to handle various fluid types and pressures. Common materials include stainless steel, brass, and plastic, each offering unique benefits. Stainless steel, for instance, is favored for its corrosion resistance and strength, making it ideal for high-pressure environments. Conversely, plastic valves are lighter and often used in less demanding settings, where their resistance to chemicals can be advantageous.

Recent studies have highlighted the importance of material selection in high-stress scenarios, such as hydrogen ball valves, where wear and tear from repeated use can significantly affect performance. Theoretical analyses and simulations have demonstrated that adhesive wear of the sealing substrates can lead to failure if the wrong materials are used. Thus, understanding the wear characteristics associated with different materials will help industries select the most appropriate manual ball valves that can withstand specific operating conditions and extend their service life.

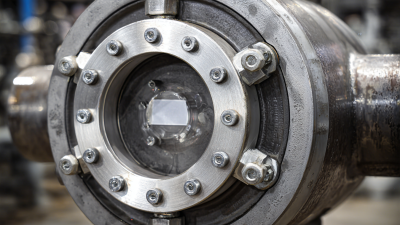

When it comes to maintaining manual ball valves, understanding the intricacies of their operation and upkeep can dramatically impact their longevity and performance. Industry reports indicate that improper maintenance can lead to a 25% increase in failure rates for these essential components. Regular inspection of the valve seals and seats, for instance, is crucial, as wear and tear can directly affect the tightness and flow control of the valve. Ensuring that ball valves are operated within their specified pressure and temperature ranges is also vital to mitigate stress and prevent premature failure.

Lubrication is another key aspect of prolonging the lifespan of manual ball valves. According to a recent maintenance guide, applying appropriate lubricants can reduce friction and wear by up to 30%. Regularly scheduled maintenance routines, including cleaning and re-lubricating the mechanical components, not only enhance performance but also help in identifying potential issues before they escalate. By adhering to these essential maintenance tips, industries can achieve optimal functionality and ensure the reliability of their valve systems for years to come.

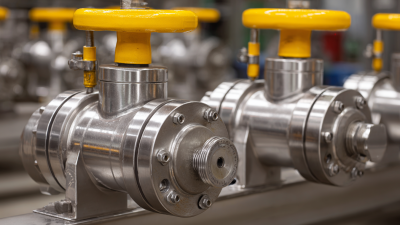

Manual ball valves play a critical role in various industries, offering reliable flow control and efficient shut-off capabilities. In the oil and gas sector, these valves are essential for managing pipelines and ensuring safety during operations. Their ability to provide a tight seal helps prevent leaks, which is crucial in environments where volatile substances are handled. The compact design and ease of operation make manual ball valves the preferred choice for maintenance and operational tasks, allowing workers to swiftly manage flow and pressure.

In the manufacturing industry, manual ball valves contribute to process optimization by regulating the flow of liquids and gases in production lines. They are commonly used in systems where precise control is necessary, such as in chemical processing, water treatment, and food production. Their robust construction ensures durability under high-pressure conditions, making them suitable for handling a wide range of substances. Additionally, the straightforward design of manual ball valves facilitates easy installation and service, making them a valuable component in enhancing overall operational efficiency across diverse industries.

| Valve Type | Materials | Size Range (inches) | Pressure Rating (PSI) | Temperature Rating (°F) | Applications |

|---|---|---|---|---|---|

| Full Port Ball Valve | Brass, Stainless Steel | 1/2 to 4 | 6000 | -20 to 400 | Water, Oil, Gas |

| Reduced Port Ball Valve | PVC, CPVC | 1/2 to 6 | 150 | 32 to 140 | Water Treatment, Chemical |

| Trunnion Ball Valve | Carbon Steel, Alloy | 2 to 12 | 2500 | -20 to 200 | Oil & Gas, Mining |

| Three-Way Ball Valve | Stainless Steel, PEEK | 1 to 4 | 1500 | -30 to 350 | HVAC, Process Control |

| Electric Actuated Ball Valve | Brass, Stainless Steel | 3/4 to 6 | 600 | -20 to 300 | Industrial Automation |

| Manual Gear Operated Ball Valve | Forged Steel, Nylon | 2 to 10 | 2000 | -20 to 300 | Pipelines, Petrochemical |

| Float Ball Valve | Plastic, Cast Iron | 1/2 to 2 | 80 | 32 to 140 | Water Supply, Irrigation |

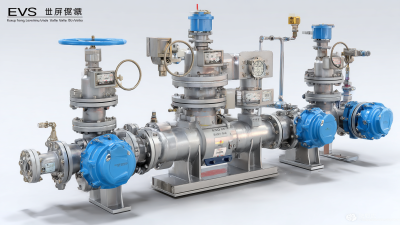

When selecting the best manual ball valves for optimal performance in your industry, it's essential to consider the brands that are renowned for their quality and reliability. Among the top recommendations are companies like Swagelok, Parker, and Apollo. These brands have built a solid reputation due to their rigorous manufacturing processes and commitment to durability. Swagelok is particularly noted for its stainless steel valves, which offer excellent corrosion resistance, making them ideal for harsh environments.

Tip: Always check for certifications and compliance with industry standards when choosing a brand. This will not only ensure quality but also enhance safety within your operations.

Another excellent choice is Velan, known for its innovative designs and leak-tight performance. Their manual ball valves cater to various applications, making them a versatile option. Additionally, brands like Hayward specialize in plastic ball valves that are perfect for chemical handling, providing cost-effective and lightweight solutions.

Tip: Consider the specific requirements of your application, such as temperature and pressure ratings, to ensure the valve you select meets the operational demands. This attention to detail will lead to improved efficiency and longevity in your system.