-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

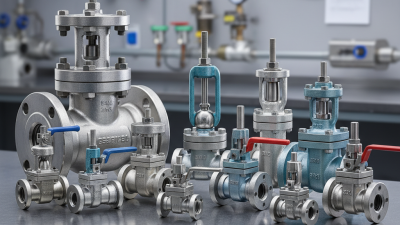

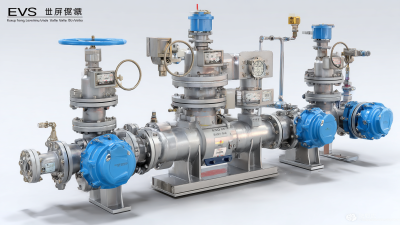

Stainless Ball Valves are essential components in plumbing and industrial applications. Their durability and corrosion resistance make them ideal for various environments. According to the latest market research by Global Industry Analysts, the demand for stainless ball valves is expected to rise by 5.4% annually until 2027. This growth reflects their importance in maintaining efficient fluid control systems.

Expert in valve technology, Dr. Emily Chen, states, "Stainless ball valves are the backbone of reliable fluid systems in homes and industries." This reinforces why selecting the right valve is crucial. Many users overlook the variety of designs and sizes available. Compromising on quality can lead to costly repairs or replacements.

In practical applications, small details matter. Consider the specific pressure limits and temperature ratings when choosing a valve. A wrong selection may lead to inefficiencies or leaks. Investing in the right stainless ball valve can significantly impact performance and longevity. It's worth taking the time to evaluate your options carefully.

Stainless ball valves are crucial in various settings. These valves control fluid flow with high precision. They are highly durable and resistant to corrosion. This feature makes them ideal for both home and industrial applications. According to a recent industry report, the global market for ball valves is expected to reach $18 billion by 2025. This reflects a steady growth trend driven by increased investments in infrastructure.

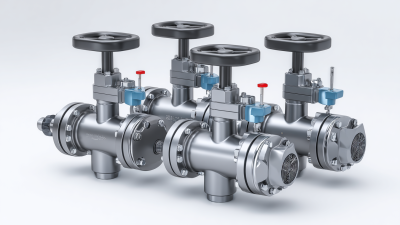

In homes, stainless ball valves are commonly found in water supply systems. They help maintain pressure and prevent leaks. Many homeowners underestimate their importance. A poorly functioning valve can lead to significant water wastage. In industrial settings, these valves manage harsh chemicals and high temperatures. The ability to handle such conditions is vital for safety and efficiency. A study showed that 30% of industrial valve failures stem from improper maintenance. Regular checks and timely replacements can enhance performance and reduce costs.

The choice of materials affects longevity. Stainless steel offers excellent strength; however, not all grades are suitable for every application. Understanding the specific requirements of your system is key. It's easy to overlook these details, leading to costly mistakes down the line. Investing time in research can pay off significantly in valve performance.

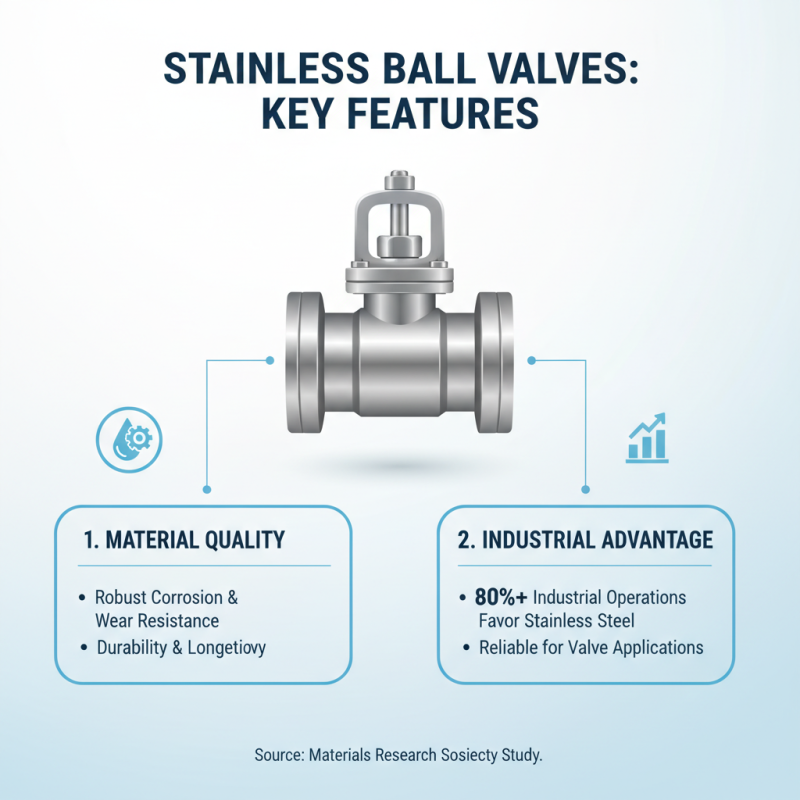

When selecting stainless ball valves, key features become critical. One major factor is the material quality. Stainless steel offers robust resistance to corrosion and wear. According to a study by the Materials Research Society, over 80% of industrial operations favor stainless steel for valve applications due to its durability and longevity.

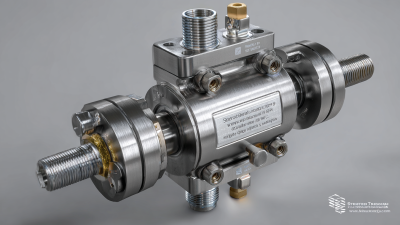

Another important feature is the valve size and connection type. Industrial applications commonly require larger sizes and specialized fittings. Research indicates that valves with standard sizing often perform better in flow control, minimizing turbulence and enhancing efficiency. Furthermore, the design of the valve, including its seat and ball, significantly affects flow rates. A well-designed valve can achieve up to 95% flow efficiency, indicating its effectiveness.

Additionally, consider the operational pressure ratings. Many applications require valves to withstand high pressures without leakage. It's essential to ensure that the valve's pressure rating is compatible with your specific needs. Misjudging this can lead to failure, posing risks in critical systems. Thoughtful selection based on these features can greatly improve system performance.

When selecting stainless ball valves, performance and durability should be your primary criteria. Stainless steel valves resist corrosion and withstand high pressures. They are ideal for home plumbing and industrial applications alike. The best options tend to have smooth operations and robust seals. This ensures minimal leakage, providing reliability across various systems.

Many valves have impressive ratings, but not all perform equally. Some may struggle under certain conditions, especially with fluctuating temperatures. Observation is key. Frequent maintenance can extend the valve's lifespan. Users often report issues when not choosing a valve suited for their specific needs. The right choice can save headaches and costly repairs down the road.

Consider the size and configuration that fits your setup. Not every valve works well in every situation. Sometimes, a compact option may seem appealing, but it could compromise flow rate. Examining installation details is vital. It’s essential to reflect on the valve's compatibility with existing systems. A slight oversight can lead to frustrating problems, so thorough research is always beneficial.

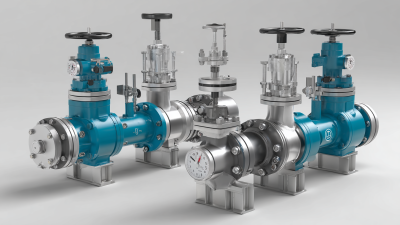

When choosing stainless ball valves, material quality and price are key factors. Evaluating different options can be tricky. Some manufacturers use lower-grade stainless steel, which might affect durability. Others may charge a premium for higher-quality materials. This discrepancy requires careful consideration.

Additionally, pay attention to the specifications. Some valves may have impressive features, but that doesn't always guarantee quality. It’s important to check certifications and reviews. Many valves look appealing, yet their performance can fall short. Users often find that a more expensive valve tends to last longer in industrial applications.

The prices of stainless ball valves can vary significantly. In some cases, a mid-range option performs just as well as a premium one. This calls into question the value of spending more. A thoughtful comparison can save money and ensure reliability. Keep in mind that selecting the right valve involves balancing cost and quality. It’s a process that requires time and careful analysis.

When selecting stainless ball valves, understanding industry standards and certifications is crucial. Various certifications indicate quality and safety. For instance, the American National Standards Institute (ANSI) sets guidelines for performance. The International Organization for Standardization (ISO) ensures uniformity in manufacturing processes. Compliance with these standards assures buyers of the product's reliability and durability.

Tips: Always check the certification labels on valves. It might save you from future issues. Look for valves that meet ANSI and ISO standards.

Another important aspect is the material composition. Not all stainless steel is the same. Type 304 and Type 316 are common grades used in ball valves. Type 316 offers better corrosion resistance, especially in harsh environments. However, the price might reflect this difference. Consider the environment where the valve will be installed before making a choice.

Tips: Assess potential corrosion risks. A small oversight can lead to significant problems later. Make informed decisions based on the specific needs of your project.

This chart represents the performance rating and certifications of various stainless ball valves based on industry standards.