-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

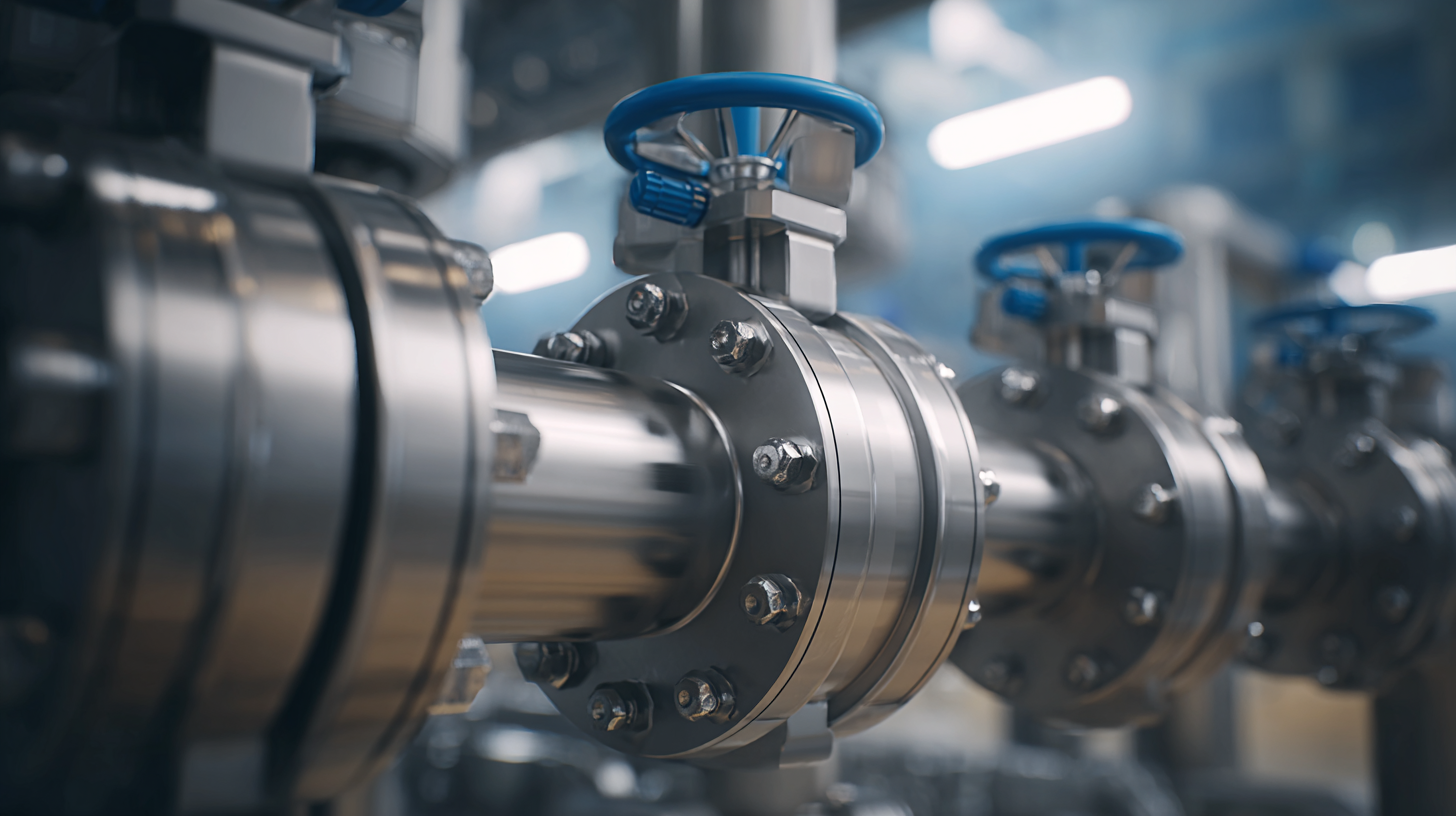

In an increasingly interconnected world, the demand for high-quality industrial components has never been more crucial. The global double ball valve market is projected to reach USD 7.67 billion by 2027, growing at a CAGR of 8.3% from 2020 to 2027, according to a recent market report. This underscores the vital role of innovations in double ball valve technology, particularly those emerging from China, where manufacturing prowess is combined with cutting-edge research and development. As the mantra "中国制造,全球共享,品质值得信赖" suggests, Chinese manufacturers are committed to elevating global standards through reliable and efficient valve solutions. By focusing on durability, performance, and sustainability, China's best double ball valve innovations are setting new benchmarks in quality, thus gaining the trust of international markets and transforming manufacturing paradigms worldwide.

The evolution of double ball valve technology in China has been marked by significant advancements, positioning the country as a leading innovator in this critical sector. According to a recent report by MarketsandMarkets, the global market for double ball valves is projected to reach $8.7 billion by 2025, with a compound annual growth rate (CAGR) of 6.5%. This growth is primarily driven by the increasing demand for efficient and reliable fluid control systems in industries such as oil and gas, water treatment, and chemical processing. China's robust manufacturing capabilities and commitment to research and development have played a pivotal role in this trend.

In the last decade, Chinese manufacturers have made remarkable strides in enhancing the performance and durability of double ball valves. A study published by the China Valve Industry Association indicates that advanced materials and innovative designs have led to a 30% improvement in valve lifespan and a significant reduction in maintenance costs. Furthermore, the implementation of smart technologies for monitoring and control has enhanced operational efficiency, making Chinese double ball valves highly competitive on the global stage. This data-driven overview highlights how China is not only meeting domestic needs but also setting a high bar for global standards in double ball valve technology.

This chart represents the advancements in double ball valve technology in China over the past decade, showcasing key innovations and their impact on global standards.

China's innovations in double ball valve technology have greatly enhanced operational efficiency across various industries. These valves, known for their durability and reliability, are now equipped with advanced features that significantly improve performance metrics. The latest designs showcase remarkable reductions in pressure loss and leakage rates, providing a substantial boost in operational efficiency. Companies leveraging these innovations can quantify their gains through metrics such as reduced downtime and operational costs, which ultimately contribute to a healthier bottom line.

China's innovations in double ball valve technology have greatly enhanced operational efficiency across various industries. These valves, known for their durability and reliability, are now equipped with advanced features that significantly improve performance metrics. The latest designs showcase remarkable reductions in pressure loss and leakage rates, providing a substantial boost in operational efficiency. Companies leveraging these innovations can quantify their gains through metrics such as reduced downtime and operational costs, which ultimately contribute to a healthier bottom line.

In addition to these mechanical advancements, the integration of intelligent electrical architecture in other industrial technologies, such as next-generation electric fracturing systems, illustrates the growing trend of combining mechanical efficiency with digital innovation. This fusion not only enhances performance but also aligns with environmental, social, and governance (ESG) goals. The streamlined drivetrains and increased power density reflect a broader move towards sustainable practices, showcasing that modern engineering not only focuses on improving efficiency but also on minimizing environmental impact. The ongoing development in these fields highlights that the rise of Chinese double ball valve innovations is part of a larger narrative of efficiency improvements across the global industrial landscape.

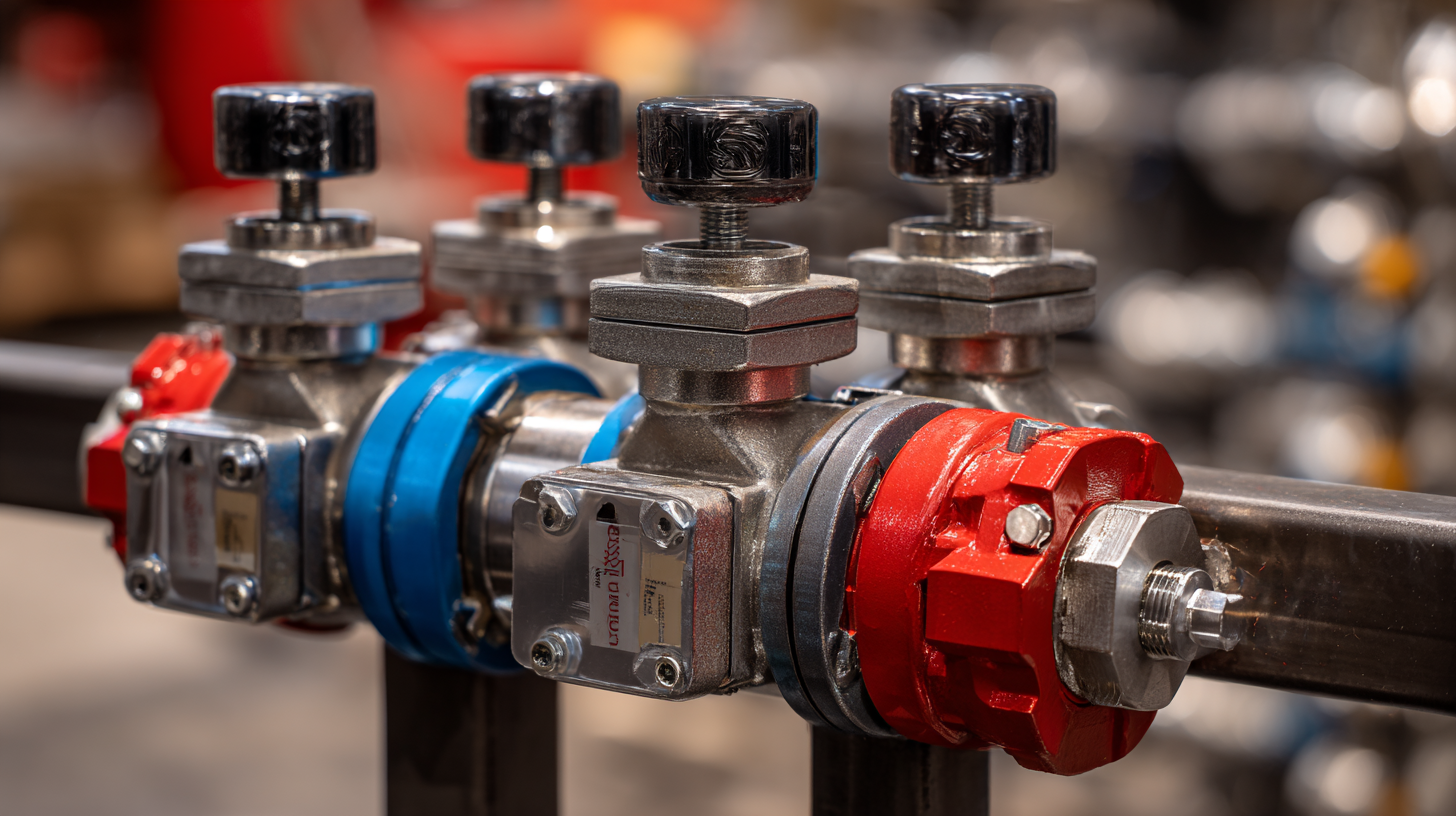

As global industries evolve, the demand for efficiency and precision has led to the rise of

smart double ball valves. These advanced valves are not just typical components; they embody the integration of technology

and engineering, poised to elevate operational standards worldwide. The ability to seamlessly monitor, control, and optimize fluid flow makes smart double

ball valves a crucial asset in sectors ranging from oil and gas to water treatment.

When considering the adoption of smart double ball valves, there are some essential tips to keep in mind. Firstly, ensure that the chosen valve is

compatible with existing systems and meets specific environmental conditions. This calibration is vital for achieving optimal performance. Secondly, prioritize valves with real-time monitoring capabilities for enhanced control and predictive maintenance, reducing downtime and operational costs.

Moreover, staying ahead of market trends is imperative. Embracing smart technologies not only improves efficiency but also positions companies as leaders

in innovation. Investing in training and development for staff ensures they are adept at managing these advanced systems, thus fully harnessing their potential and ultimately driving better business outcomes.

China is rapidly emerging as a leader in eco-friendly valve manufacturing, particularly in the double ball valve sector. As industries worldwide increasingly focus on sustainability, China's innovative approaches are setting new standards. According to a recent report by the Global Valve Industry Association, nearly 60% of valve manufacturers are adopting sustainable practices, with China at the forefront of this transformation. These innovations not only enhance performance but also reduce the carbon footprint associated with valve production.

One notable advancement is the integration of eco-friendly materials and energy-efficient manufacturing processes. A study published in the Journal of Clean Production indicates that by 2025, the use of biodegradable materials in valve production could reduce overall waste by up to 30%. Additionally, Chinese manufacturers are investing heavily in automated technologies that minimize energy consumption, reportedly leading to energy savings of about 25% per unit produced. These efforts not only contribute to global sustainability goals but also create competitive advantages for Chinese manufacturers in the international marketplace.

As the demand for innovative solutions in various industries continues to grow, the double ball valve market is no exception. With the increasing emphasis on quality and efficiency, the future prospects for double ball valve innovations appear promising. Manufacturers are increasingly investing in research and development to enhance the functionality and durability of these valves, catering to a diverse range of applications from water distribution to industrial processes. This commitment to innovation not only improves operational performance but also aligns with global industry standards.

Moreover, parallels can be drawn between the rising popularity of products like camel milk and the evolving market for double ball valves. As health consciousness among consumers increases, the demand for high-quality, reliable products surges. This trend encourages manufacturers to adopt cutting-edge technologies and sustainable practices in their production processes. As the market evolves, it is crucial for companies to stay ahead of emerging trends to meet the growing expectations of consumers and businesses alike, ensuring they remain competitive in a rapidly changing environment.

| Year | Innovation Type | Expected Growth Rate (%) | Market Demand (Units) | Key Features |

|---|---|---|---|---|

| 2023 | Smart Control Valves | 15% | 50,000 | Remote Monitoring, IoT Integration |

| 2024 | Eco-Friendly Materials | 12% | 55,000 | Recyclable Materials, Reduced Carbon Footprint |

| 2025 | Automated Operations | 18% | 60,000 | Full Automation, AI Optimization |

| 2026 | High-Pressure Resistance | 10% | 65,000 | Enhanced Durability, Safety Features |

| 2027 | Customizable Designs | 20% | 70,000 | Tailored Solutions, Versatile Applications |