-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

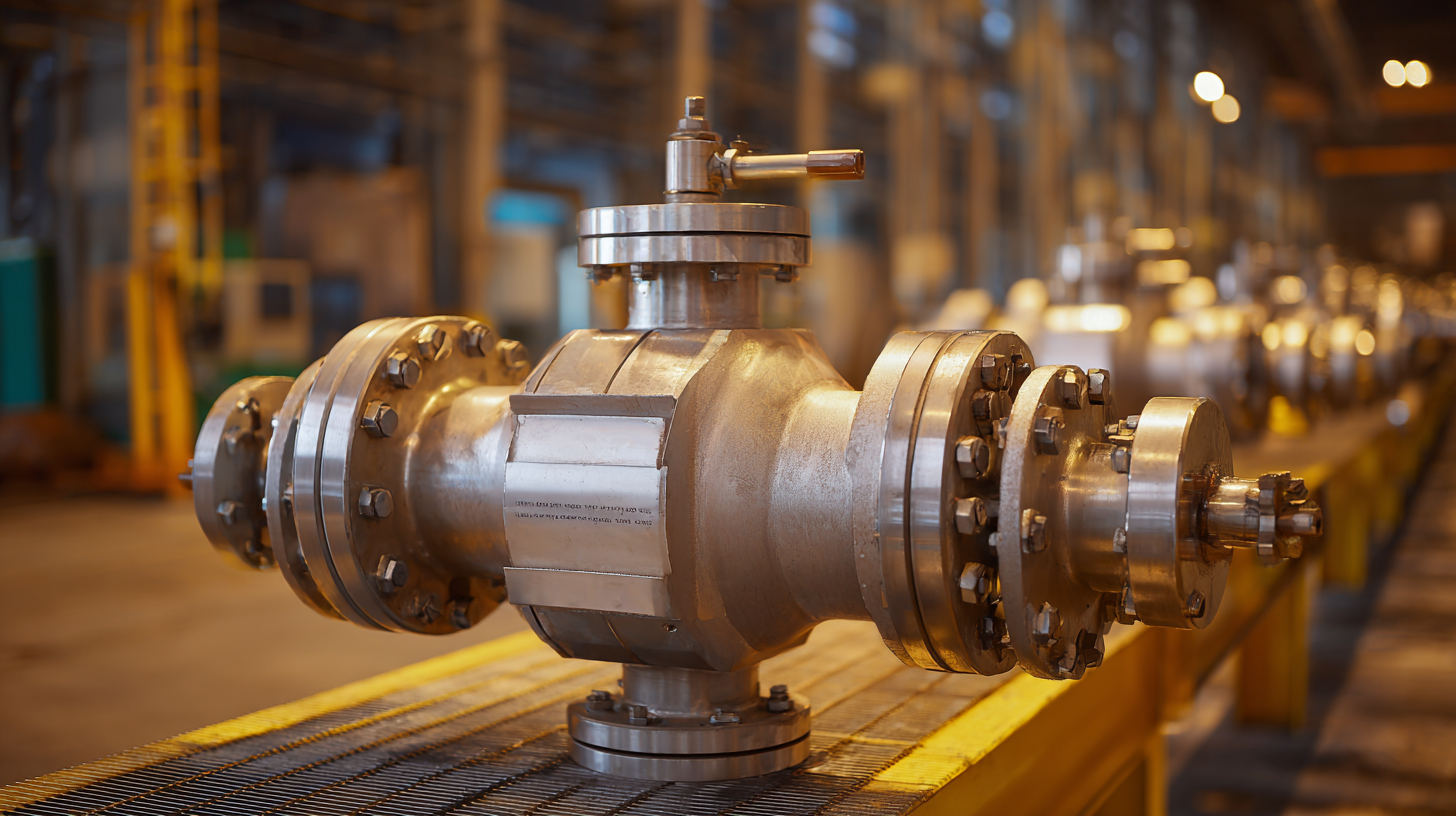

In the industrial sector, the selection of a High Temperature Ball Valve can significantly impact operational efficiency and safety. According to a report by Market Research Future, the global valve market is projected to reach approximately $97 billion by 2026, with high-temperature variants being a key segment due to their critical applications in sectors such as oil and gas, chemical processing, and power generation. These environments often require valves that can withstand extreme temperatures and pressures while maintaining reliability and performance.

As industries continue to prioritize efficiency and sustainability, the importance of choosing the right high temperature ball valve cannot be overstated. Understanding the essential factors in this selection process is vital for ensuring optimal functionality and longevity in demanding applications.

High temperature ball valves are crucial components in various industrial applications, particularly in sectors such as oil and gas, chemical processing, and power generation. These valves are engineered to operate efficiently in extreme temperatures, often exceeding 200°C (392°F), which is essential for maintaining process integrity and safety. According to a recent study by the Industrial Valve Manufacturer's Association (IVMA), nearly 30% of valve failures in high-temperature environments can be attributed to improper selection and installation, highlighting the need for careful consideration when choosing these critical components.

In the energy sector, for instance, high temperature ball valves play a vital role in steam control systems, where they must withstand both high pressure and temperature cycles. A report from the Global Energy Council indicates that improperly functioning valves in these applications can lead to a 10-20% decrease in efficiency, translating to significant financial losses and safety hazards. Therefore, understanding the specific operating conditions and material specifications is essential for ensuring longevity and reliability in high temperature ball valves, ultimately leading to enhanced operational performance and reduced downtime.

| Tip | Description | Material | Temperature Rating (°C) | Applications |

|---|---|---|---|---|

| 1. Determine Temperature Requirements | Identify the maximum operating temperature for your application. | Stainless Steel | -200 to 400 | Oil and Gas |

| 2. Assess Compatibility with Fluids | Ensure the valve material is compatible with the fluids being handled. | Carbon Steel | -29 to 200 | Chemical Processing |

| 3. Evaluate Pressure Ratings | Choose a valve that can withstand the necessary pressure levels. | Alloy Steel | -50 to 350 | Power Generation |

| 4. Consider Valve Size and Configuration | Select the appropriate size and configuration for your system's needs. | PVC | 0 to 60 | Water Treatment |

| 5. Review Maintenance Requirements | Understand the maintenance needs for long-term operation. | Bronze | -10 to 250 | HVAC Systems |

When selecting high temperature ball valves, several key factors must be taken into account to ensure optimal performance and longevity in demanding environments. Firstly, the material of the valve is crucial; it should be able to withstand elevated temperatures without compromising structural integrity. Materials such as stainless steel or exotic alloys are often recommended for their heat resistance and durability. Additionally, the seal material must also be evaluated, as it plays a pivotal role in preventing leaks, especially in high-temperature applications. PTFE or other specialized compounds are typically used for their excellent thermal and chemical resistance.

Another important consideration is the valve's pressure rating. High temperatures can affect the pressure capabilities of a valve, so it’s essential to choose a model that can handle both the pressure and temperature extremes of your specific application. Furthermore, the valve's design and size should meet the flow requirements of your system to avoid any operational issues. Lastly, it's beneficial to review the manufacturer's reputation and warranty offering; a reliable supplier can provide both assurance and support for your high temperature ball valve choices.

When selecting materials for high-temperature ball valves, it is crucial to focus on components that can withstand the extreme conditions they will encounter. High temperatures can lead to material degradation, compromising the integrity and functionality of the valve. Therefore, choosing materials like stainless steel, Inconel, or Monel is often advisable due to their superior heat resistance and mechanical properties. Stainless steel offers excellent corrosion resistance and strength, making it a popular choice for many applications.

Furthermore, don’t overlook the importance of sealing materials in high-temperature environments. Traditional elastomers may not be suitable, as they can lose elasticity and resilience under heat. Instead, consider options such as PTFE or graphite-based seals, which are designed to maintain their properties even in extreme temperatures. By ensuring that both the body and sealing components are made from appropriate materials, you enhance the durability and reliability of the high-temperature ball valve, ultimately leading to better performance and reduced maintenance costs.

When selecting a high temperature ball valve, understanding valve specifications and performance ratings is critical to ensuring optimal operation in extreme conditions. First, consider the material composition of the valve body and internal components. High temperatures often lead to thermal expansion and material degradation, so choosing valves made from robust materials, such as stainless steel or special alloys, is essential. Additionally, ensure the seal materials are compatible with high temperatures to prevent leaks and ensure durability.

Performance ratings provide insight into how a valve will behave under operational stress. Investigate the Maximum Operating Temperature (MOT) and the pressure rating, as these factors significantly impact the valve's ability to perform reliably in high-temperature environments. Furthermore, look for valves that have undergone rigorous testing for fatigue and wear, which can provide assurance of long-term performance. By carefully evaluating these specifications and performance ratings, you can make informed decisions that enhance system efficiency and reduce the risk of failures.

When it comes to high temperature ball valves, proper maintenance is crucial for ensuring their longevity and optimal performance. Regular inspection is paramount; operators should routinely check for signs of wear and tear, leaks, or unusual noises. This proactive approach allows for timely repairs and can prevent more extensive damage down the line. Additionally, keeping a close eye on the valve seals is essential, as seals can degrade due to high temperatures and pressure fluctuations, leading to performance issues.

Lubrication plays a vital role in the maintenance of high temperature ball valves. Using the correct type of lubricant designed for extreme conditions can significantly reduce friction, allowing for smoother operation and extending the valve's service life. Furthermore, operators should familiarize themselves with the manufacturer’s guidelines for maintenance scheduling. Regularly scheduled maintenance not only keeps the valves operating efficiently but also helps in identifying potential problems before they escalate, ensuring that the system remains reliable under high-temperature conditions.

The following chart illustrates the importance of various factors to consider when choosing high temperature ball valves. Each factor is rated based on its significance for ensuring optimal performance and longevity.