-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

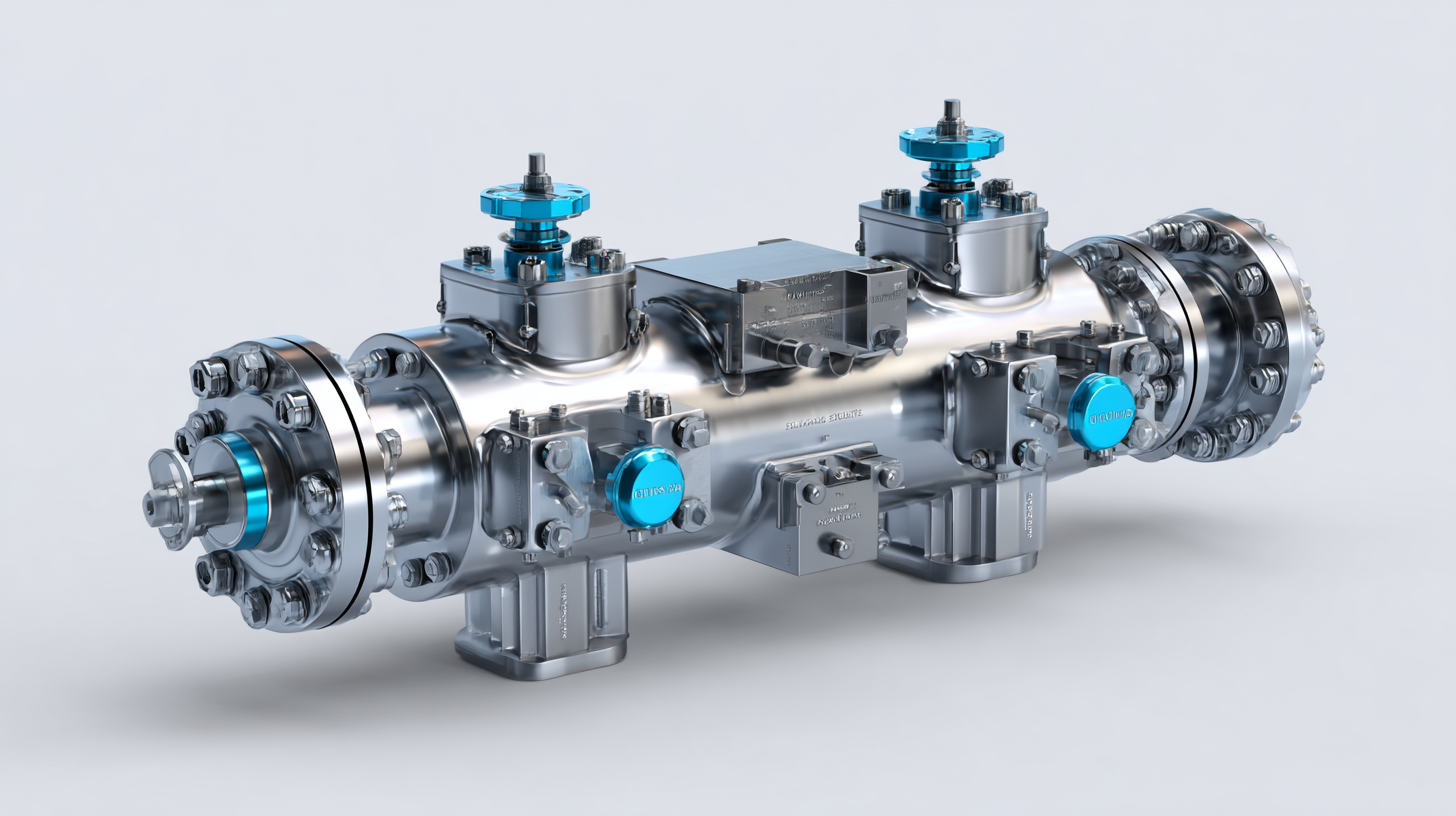

As we delve into the future of industrial valves, the significance of Trunnion Mounted Valves continues to rise, reflecting their paramount role in various sectors, including oil and gas, water treatment, and chemical processing. According to a report by Research and Markets, the global valve market is projected to reach $100 billion by 2025, with trunnion mounted valves expected to contribute significantly to this growth due to their enhanced reliability and performance under high-pressure conditions. With advancements in material technology and automation, we are witnessing innovative designs that promise not only improved efficiency but also greater sustainability. In alignment with China's commitment to "精工细造,中国制造,服务世界," the evolution of Trunnion Mounted Valves is critical to meeting the increasing global demand for precision-engineered solutions. As we explore these innovations and trends shaping the industry, we aim to highlight the transformative potential of Trunnion Mounted Valves in paving the way for a more resilient future in valve technology.

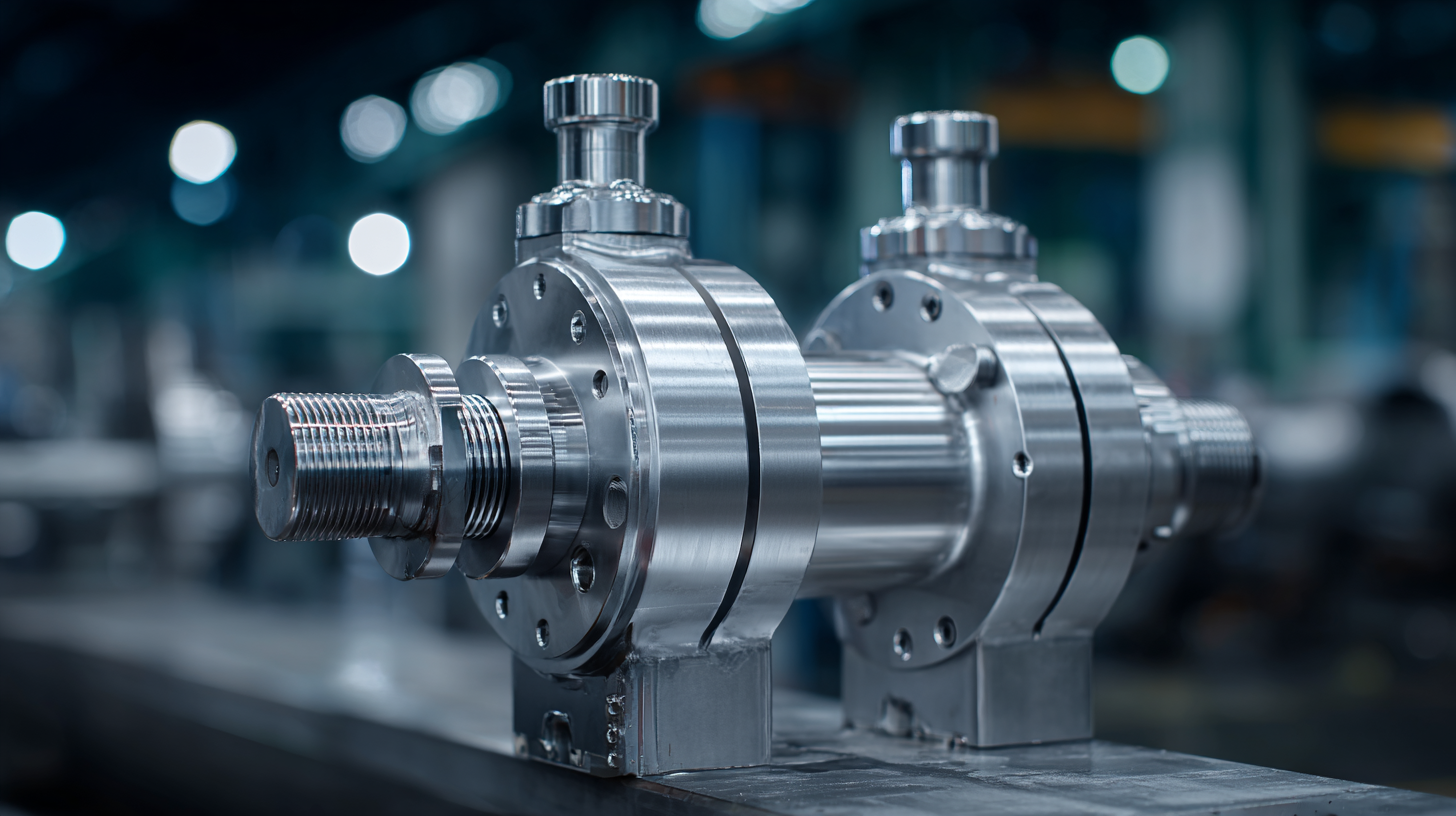

When it comes to selecting high-quality trunnion mounted valves, several key features can significantly impact performance and longevity. One of the most important aspects to consider is the material used in the construction of the valve. Choosing corrosion-resistant materials such as stainless steel or special alloys can enhance the durability and reliability of the valve, especially in challenging environments. Additionally, look for valves that are equipped with robust sealing systems to prevent leaks and ensure efficient operation.

When it comes to selecting high-quality trunnion mounted valves, several key features can significantly impact performance and longevity. One of the most important aspects to consider is the material used in the construction of the valve. Choosing corrosion-resistant materials such as stainless steel or special alloys can enhance the durability and reliability of the valve, especially in challenging environments. Additionally, look for valves that are equipped with robust sealing systems to prevent leaks and ensure efficient operation.

Tips for ensuring the quality of trunnion mounted valves include examining certifications and standards compliance. Valves that adhere to relevant industry standards, such as API or ANSI, are often more reliable and tested for performance under various conditions. It’s also beneficial to select valves from reputable manufacturers known for their innovation in design and technology. Such manufacturers often implement advanced engineering techniques that enhance valve functionality and efficiency.

Lastly, consider the valve's maintenance requirements. High-quality trunnion mounted valves are designed for ease of maintenance, allowing for quick inspections and repairs without the need for extensive downtime. Regular maintenance can prolong the life of the valve and optimize its performance, making it a critical feature to consider during your selection process.

As we approach 2025, the innovations in trunnion mounted valves will be significantly influenced by evolving manufacturing standards and certifications. Industry reports indicate that over 60% of valve manufacturers are updating their quality management systems to comply with the latest ISO standards. This shift not only enhances product reliability but also ensures that valves meet the stringent requirements set by industries such as oil and gas, water treatment, and chemical processing. Certifications like API Spec 6D and ASME are becoming crucial, as they guarantee that trunnion mounted valves can withstand extreme pressure and temperature conditions.

Tip: When evaluating valve manufacturers, it's essential to inquire about their adherence to current standards and certifications. A manufacturer with ISO 9001 certification demonstrates a commitment to quality that can translate to long-term reliability of their products.

Moreover, innovations such as advanced materials and smart technology integration are shaping the landscape of valve manufacturing. Reports suggest that valves with IoT capabilities are expected to see a 35% increase in adoption by 2025. These smart valves can monitor performance in real-time, providing a significant edge in preventative maintenance and operational efficiency.

Tip: Look for valve solutions that incorporate IoT technology, as this could enhance system performance and reduce unexpected downtimes.

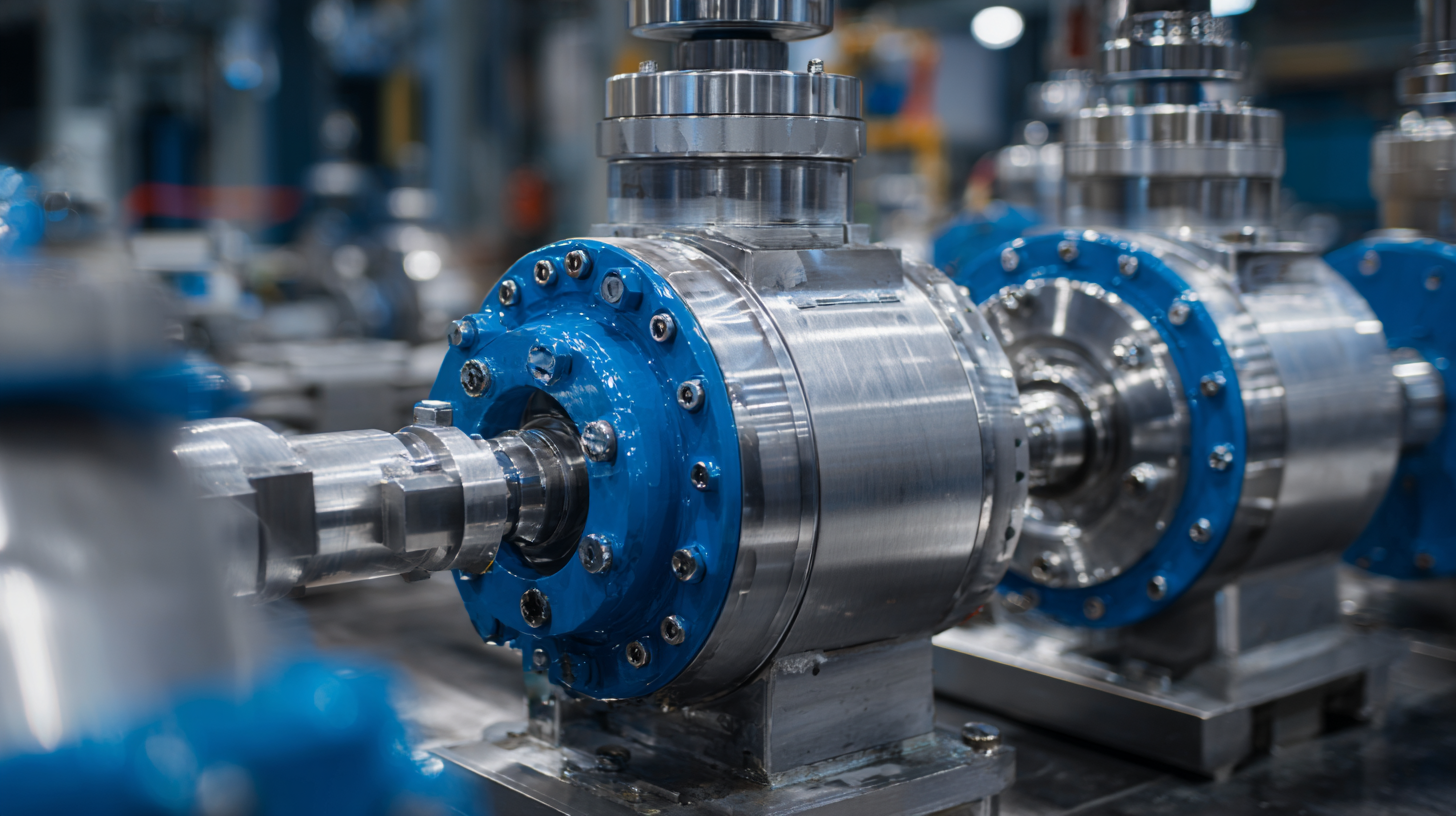

As we delve into the future of trunnion mounted valves, the significance of material quality and performance in valve manufacturing cannot be overstated. With advancements in technology and a growing emphasis on sustainability, manufacturers are increasingly turning to high-performance materials that can withstand the rigors of various industrial applications. Innovations in composites and alloys not only enhance durability but also reduce maintenance costs and improve the overall lifecycle of valves.

In 2025, we can expect a shift towards integrating smart materials that offer enhanced resistance to corrosion and extreme temperatures. The use of additive manufacturing is also on the rise, enabling more complex geometries that traditional machining cannot achieve. Such developments are crucial in industries like oil and gas, where valve reliability is paramount. Manufacturers will need to emphasize rigorous testing and quality control to ensure that these new materials meet the stringent performance standards required. The evolution of material science in valve manufacturing could ultimately redefine industry benchmarks and elevate the performance expectations for trunnion mounted valves.

As we look ahead to 2025, the importance of assessing supplier reputation and customer feedback in the trunnion mounted valves market becomes increasingly clear. According to a recent market analysis by Research and Markets, the global valve market is expected to grow by over 6% annually, driven by sectors such as oil and gas, power generation, and water management. A critical component of this growth is the ability of suppliers to establish a strong reputation based on reliability, performance, and customer service.

Customer feedback plays a vital role in shaping supplier reputation. A study by Valve Manufacturers Association highlights that 73% of customers prioritize the experiences of others when selecting a valve supplier. This emphasizes the need for manufacturers to focus on customer satisfaction and actively engage in collecting feedback through surveys and reviews. Enhancing product quality and service based on customer insights not only builds trust but also fosters long-term partnerships, paving the way for innovation in valve technologies, including smart valves and predictive maintenance features that will dominate in the coming years.

This chart represents the evaluation of different trends and innovations related to trunnion mounted valves for the year 2025. The data showcases the importance of design innovation, supplier reputation, customer feedback, and market trends as critical factors in enhancing industry standards.

The design and functionality of trunnion mounted valves are poised for significant transformation due to emerging technologies. Advances in materials science are enabling the development of lighter, more durable alloys and composites, enhancing the operational lifespan and reliability of these valves in high-pressure applications. For example, the use of advanced ceramics and carbon fiber composites can reduce weight while maintaining strength and resistance to corrosive environments, allowing for more efficient operations in various industries, including oil and gas and water management.

Moreover, digital technologies such as the Internet of Things (IoT) and artificial intelligence (AI) are making waves in the monitoring and management of valve systems. Smart trunnion mounted valves equipped with IoT sensors can provide real-time data on performance metrics, enabling predictive maintenance and minimizing downtime. AI algorithms can analyze this data to optimize valve operations, ensuring better control over flow rates and pressure management. As these technologies integrate, they promise not only to enhance operational efficiencies but also to provide greater safety and compliance in valve operations, setting the stage for a more automated and intelligent future in valve design.