-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

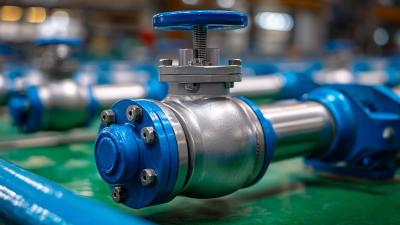

In the industrial sector, the selection of appropriate valves is crucial for optimizing system performance and ensuring safety. Among the various types of valves, the Wafer Ball Valve stands out due to its compact design, cost-effectiveness, and efficient operation. According to a report by MarketsandMarkets, the global valve market is projected to reach $150 billion by 2025, with a significant increase in demand for durable and high-performance options like the Wafer Ball Valve. This valve type is especially favored in applications such as water treatment, oil and gas, and chemical processing, where space constraints and pressure requirements necessitate reliable solutions. Understanding the specific requirements and characteristics of Wafer Ball Valves can significantly enhance operational efficiency and longevity, making them an ideal choice for various industrial applications.

Wafer ball valves play a critical role in industrial applications by facilitating efficient flow control with minimal pressure drop. Their unique design allows for easy installation between flanges without requiring additional support. According to a report by MarketsandMarkets, the global ball valve market is projected to reach USD 8.7 billion by 2025, driven by the growing demand for flow control solutions in various industries such as oil and gas, water and wastewater, and chemical processing. This trend underscores the essential functionality of wafer ball valves, especially in applications requiring robust performance under high pressures and temperatures.

In industrial settings, wafer ball valves are favored for their compact structure and reliability. They offer excellent sealing capabilities and can handle a wide range of fluids, including slurries and corrosive materials. A study published by Research and Markets highlighted that the adoption of automated wafer ball valves is increasing, with an expected growth rate of over 7% annually, reflecting the industry's shift towards automation and smart manufacturing. The advanced design of these valves allows them to operate effectively in varying conditions, making them a vital component for maintaining system integrity and safety in complex industrial processes.

When selecting wafer ball valves for industrial applications, several key factors need to be taken into account to ensure optimal performance and longevity. First and foremost, the materials of construction play a critical role. According to a report by the Valve Manufacturers Association, valves made from stainless steel or high-performance plastic show superior corrosion resistance and durability, which are essential for harsh environments. Understanding the specific media and conditions, such as temperature and pressure, will dramatically influence your choice of materials.

Another significant factor is the valve size and connection type. Proper sizing based on flow requirements is crucial; valves that are too small may restrict flow, causing pressure drops and inefficiencies. The American National Standards Institute (ANSI) recommends consulting flow coefficient (Cv) values during selection to ensure compatibility with your system.

**Tips:** Always verify the maximum pressure and temperature ratings of the wafer ball valve to avoid operational failures. Additionally, consider the ease of maintenance – options with replaceable seals and easy disassembly can reduce downtime during routine checks. Lastly, aim to choose valves from reputable manufacturers who provide certifications and warranties, helping to safeguard against costly failures due to poor quality.

When selecting the ideal wafer ball valve for industrial applications, understanding the material options available is crucial. The durability and cost of valve materials can significantly impact operational efficiency and long-term maintenance. Common materials for wafer ball valves include stainless steel, carbon steel, and various plastic composites. Stainless steel, while more expensive, offers superior corrosion resistance, making it suitable for harsh environments often found in the photovoltaic industry where exposure to chemicals and outdoor conditions is common.

Many industrial applications in the photovoltaic sector demand valves that can withstand high pressure and temperature fluctuations. As stated in recent industry reports, the increasing demand for solar energy systems has led to innovations in valve design, ensuring they meet the rigorous standards while remaining cost-effective. It's essential to balance the upfront investment with the potential for reduced operational costs over time.

**Tip 1:** Consider the environment in which the valve will operate. If exposure to corrosive substances is likely, investing in high-quality materials such as stainless steel will pay off in the long run.

**Tip 2:** Evaluate the lifespan and maintenance requirements of different materials. While cheaper options may save you money initially, they might require more frequent replacements or repairs, increasing overall costs.

| Material Type | Durability Rating | Temperature Resistance (°C) | Cost per Unit ($) | Best Application |

|---|---|---|---|---|

| Stainless Steel | Excellent | -196 to 450 | 75 | High-pressure applications |

| Carbon Steel | Good | -30 to 400 | 50 | General industrial use |

| PVC | Fair | 0 to 60 | 15 | Chemical processes |

| Bronze | Good | -20 to 300 | 65 | Marine applications |

| PTFE (Teflon) | Excellent | -200 to 260 | 95 | Highly corrosive fluids |

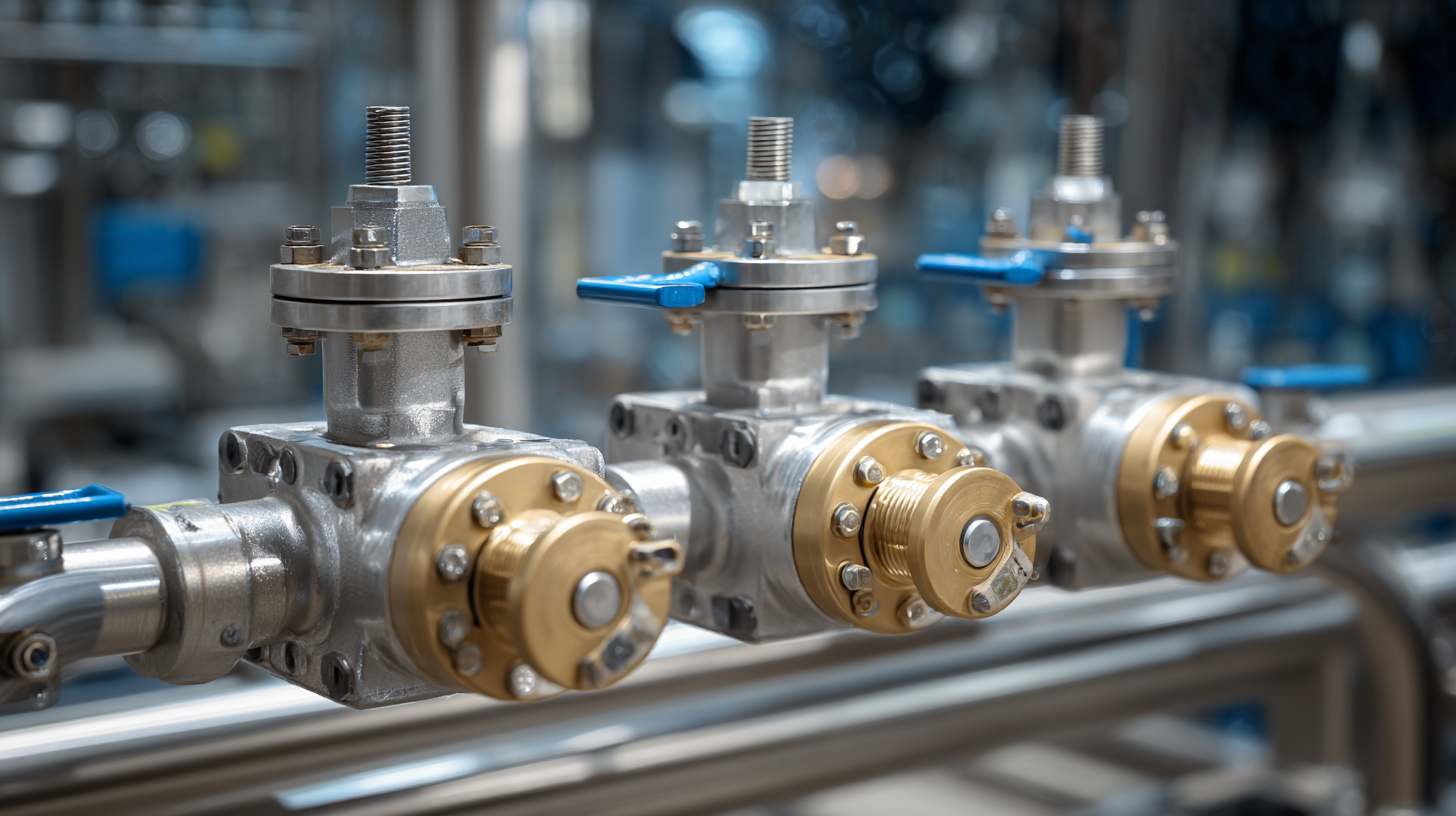

When selecting a wafer ball valve for industrial applications, understanding the size and configuration options is crucial for ensuring optimal performance. Wafer ball valves are designed to fit between flanges, making their size selection directly dependent on the piping system they will be integrated into. Accurate sizing involves measuring the valve's diameter to match the nominal pipe size, typically using standards such as ANSI or DIN. Maintaining proper size is vital, as mismatched sizing can lead to flow restrictions, pressure drops, or inefficient system operation.

Configuration choices are equally important when selecting a wafer ball valve. These valves can be classified based on various design elements, including body material, valve operation type (manual or actuated), and seat design. The choice of material often depends on the type of media the valve will control, with options ranging from stainless steel for corrosive fluids to PVC for chemical applications. Furthermore, the configuration should account for the operating conditions, such as temperature, pressure, and flow rate. A thorough assessment of these factors ensures that the chosen valve operates effectively within the desired parameters, enhancing the reliability and efficiency of the overall system.

This bar chart illustrates the flow rate capacity of various wafer ball valve sizes, highlighting how size impacts performance in industrial applications. Selecting the appropriate size is crucial for optimizing flow and ensuring efficient operation.

When selecting the ideal wafer ball valve for industrial applications,

evaluating the manufacturer's reputation and reliability is paramount.

According to a report from Market Research Future,

the global valve market is expected to reach USD 87.34 billion by 2023,

driven by the increasing demand for efficient and reliable fluid control systems.

A manufacturer's standing in the industry often correlates with the quality and longevity of their products.

Companies with a proven track record frequently utilize advanced manufacturing techniques and rigorous testing standards

to ensure their valves meet industry specifications.

Additionally, organizations like the International Organization for Standardization (ISO)

provide frameworks that assist in assessing a manufacturer’s credibility.

Manufacturers adhering to ISO 9001 standards

typically display a commitment to quality management principles, which include customer satisfaction and continuous improvement processes.

Reviews and case studies from unbiased sources can offer insights into the reliability of specific brands.

Invest time in researching and choosing manufacturers that have been recognized for their innovation and reliability;

this can significantly impact the efficiency and safety of your industrial applications.