-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In the realm of industrial fluid control systems, the performance efficiency of valves is paramount, and the Screwed Ball Valve stands out as a critical component. This article aims to delve into the various aspects of Screwed Ball Valves, examining key industry metrics that define their operational efficacy. By understanding these metrics, such as flow coefficients, pressure drop rates, and durability standards, manufacturers and engineers can make informed decisions that enhance system performance and longevity. Additionally, the benefits of using Screwed Ball Valves, including ease of installation, maintenance simplicity, and reliability under varying operating conditions, will be explored. This analysis will provide a comprehensive overview of how to maximize the effectiveness of Screwed Ball Valves in various applications, ensuring optimal functionality and performance in fluid transport and control.

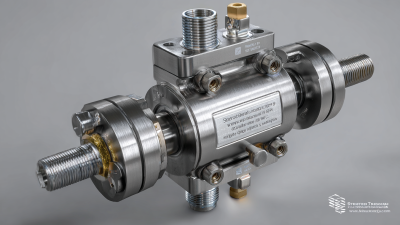

Screwed ball valves are essential components in fluid control applications, known for their reliable performance and efficiency. One of their key characteristics is the design that allows for minimal flow resistance, enabling a smooth and efficient flow of liquids or gases through the system. The spherical shape of the valve provides an optimal sealing surface, reducing the risk of leakage and enhancing the reliability of processes across various industries.

Screwed ball valves are essential components in fluid control applications, known for their reliable performance and efficiency. One of their key characteristics is the design that allows for minimal flow resistance, enabling a smooth and efficient flow of liquids or gases through the system. The spherical shape of the valve provides an optimal sealing surface, reducing the risk of leakage and enhancing the reliability of processes across various industries.

Another significant trait of screwed ball valves is their ease of operation and maintenance. Typically, these valves can be quickly opened or closed with a simple quarter turn, allowing for rapid adjustments in fluid flow. Additionally, the construction of screwed ball valves often facilitates easier disassembly and cleaning, which is particularly advantageous in industries like food processing or pharmaceuticals, where hygiene and compliance with safety regulations are paramount. These features make screwed ball valves a preferred choice for ensuring operational efficiency and reliability in complex fluid control systems.

When evaluating the efficiency of screwed ball valves, several critical performance metrics must be considered. One of the primary indicators is the flow coefficient (Cv), which represents the flow capacity of the valve. Industry studies indicate that a higher Cv value correlates with reduced pressure drop across the valve, enhancing overall system efficiency. According to a 2022 report by the Valve Manufacturers Association (VMA), well-designed screwed ball valves can achieve Cv values up to 400 for larger bore sizes, illustrating their suitability for high-flow applications.

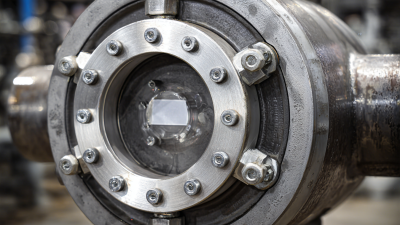

Another significant metric is the leakage rate, specifically for closed position applications. It is crucial to ensure that the valve effectively prevents any undesired fluid bypass. Recent tests find that leading manufacturers provide screwed ball valves with leakage rates as low as 0.1% to 0.2% of the maximum flow, which is essential in applications demanding stringent control over fluid integrity. Furthermore, factoring in the material choice, the use of bi-directional sealing can significantly enhance the performance efficiency, as reported in a 2023 industry analysis, emphasizing tailored materials for specific operation environments. By focusing on these critical metrics, industry professionals can make informed decisions, ensuring optimal performance in their applications.

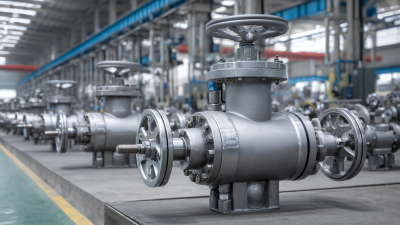

The material selection for screwed ball valves plays a critical role in their performance efficiency, impacting not only durability but also functionality under various operating conditions. According to a report by the International Journal of Pressure Vessels and Piping, valves made from high-grade stainless steel can withstand significantly higher pressures and temperatures, resulting in a performance increase of up to 30% compared to those made from lower-quality materials. This is crucial in industries such as oil and gas, where equipment often faces harsh conditions.

When choosing materials for screwed ball valves, it’s essential to consider both the chemical compatibility and mechanical properties. For instance, using materials like PTFE (polytetrafluoroethylene) for seals can enhance leak resistance and reduce friction, thereby improving the overall lifespan of the valve. As per the Valve Manufacturers Association, employing premium alloys in valve construction can lead to a reduction in maintenance costs by approximately 20%, making upfront investments more viable in the long run.

Tips: Always consult with material experts when selecting components for ball valves to ensure they meet the specific needs of your application. Additionally, consider the long-term performance metrics rather than just initial costs; a durable valve can save significant expenses over time through reduced downtime and maintenance.

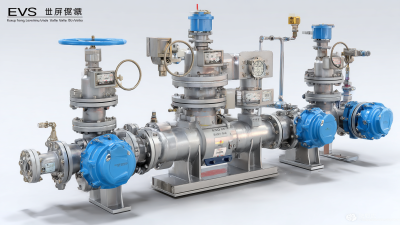

Screwed ball valves offer numerous advantages that significantly enhance their utility in industrial settings. One of the primary benefits is their robust design, which allows for reliable sealing under high pressure and temperature conditions. This reliability minimizes the risk of leaks, ensuring safe and efficient operation in critical applications. Furthermore, the straightforward installation process of screwed ball valves reduces downtime, enabling quicker integration into existing systems and facilitating regular maintenance.

Another key aspect of screwed ball valves is their versatility. They can handle a wide range of fluids, including gases, liquids, and slurries, making them suitable for various industries, from oil and gas to water treatment. Their ability to provide tight shut-off and low flow resistance optimizes system performance, contributing to energy savings and reduced operational costs. Additionally, their straightforward operation, typically requiring only a quarter-turn to open or close, enhances user convenience and minimizes the training needed for personnel.

In comparing screwed ball valves to other valve types, it becomes clear that their design offers several performance advantages. Screwed ball valves are known for their robust construction and reliable sealing capabilities, which make them particularly well-suited for demanding applications in industries such as oil and gas, and increasingly, in hydrogen technology. Their efficient flow characteristics enable minimal pressure drop, a critical factor in optimizing systems for cleaner energy solutions.

One key aspect to consider is that while other valve types, such as gate valves, may be less expensive initially, they often lack the tight shut-off that ball valves provide. This differential can impact long-term operational costs, especially in applications focused on sustainability and efficiency. Furthermore, the increasing focus on hydrogen technologies underlines the importance of using valves that can withstand high pressures and corrosive environments, where the superiority of screwed ball valves truly shines.

Tips: When selecting valves for your applications, prioritize those that comply with the latest industry standards to ensure compatibility with evolving technologies. Regular maintenance can also enhance the performance and longevity of your valves, reducing the likelihood of costly downtime. Remember to evaluate the specific requirements of your system to choose the most suitable valve type for optimal efficiency.