-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

In the realm of industrial applications, the choice of valve technology significantly impacts operational efficiency and reliability. Among various options available, the Split Body Ball Valve stands out due to its unique design and functional advantages. According to a recent report by MarketsandMarkets, the global ball valve market is projected to reach USD 14.63 billion by 2025, with a notable segment driven by the increasing adoption of split body designs in various industries, including oil and gas, chemicals, and water treatment.

In the realm of industrial applications, the choice of valve technology significantly impacts operational efficiency and reliability. Among various options available, the Split Body Ball Valve stands out due to its unique design and functional advantages. According to a recent report by MarketsandMarkets, the global ball valve market is projected to reach USD 14.63 billion by 2025, with a notable segment driven by the increasing adoption of split body designs in various industries, including oil and gas, chemicals, and water treatment.

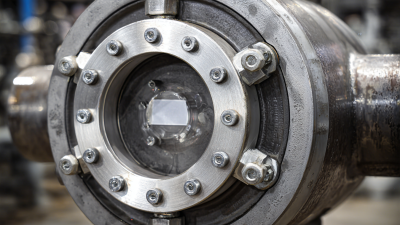

The Split Body Ball Valve offers advantages such as ease of maintenance, reduced downtime, and enhanced performance under high pressure and temperature conditions. By enabling the valve body to be split into two halves, it allows for straightforward internal access without needing to remove the entire valve from the pipeline. Whether dealing with flow control or isolation purposes, understanding these intrinsic benefits is crucial for industry professionals seeking to optimize their systems and minimize operational risks.

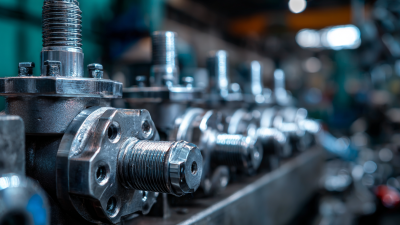

Split body ball valves are increasingly recognized for their unique advantages in industrial applications, offering a range of key features that enhance operational efficiency and reliability. One significant aspect of these valves is their design, which allows for easy maintenance and replacement of internal components without the need to dismantle the entire valve from the pipeline. This feature significantly reduces downtime and maintenance costs, making them highly desirable in industries where uninterrupted processes are crucial.

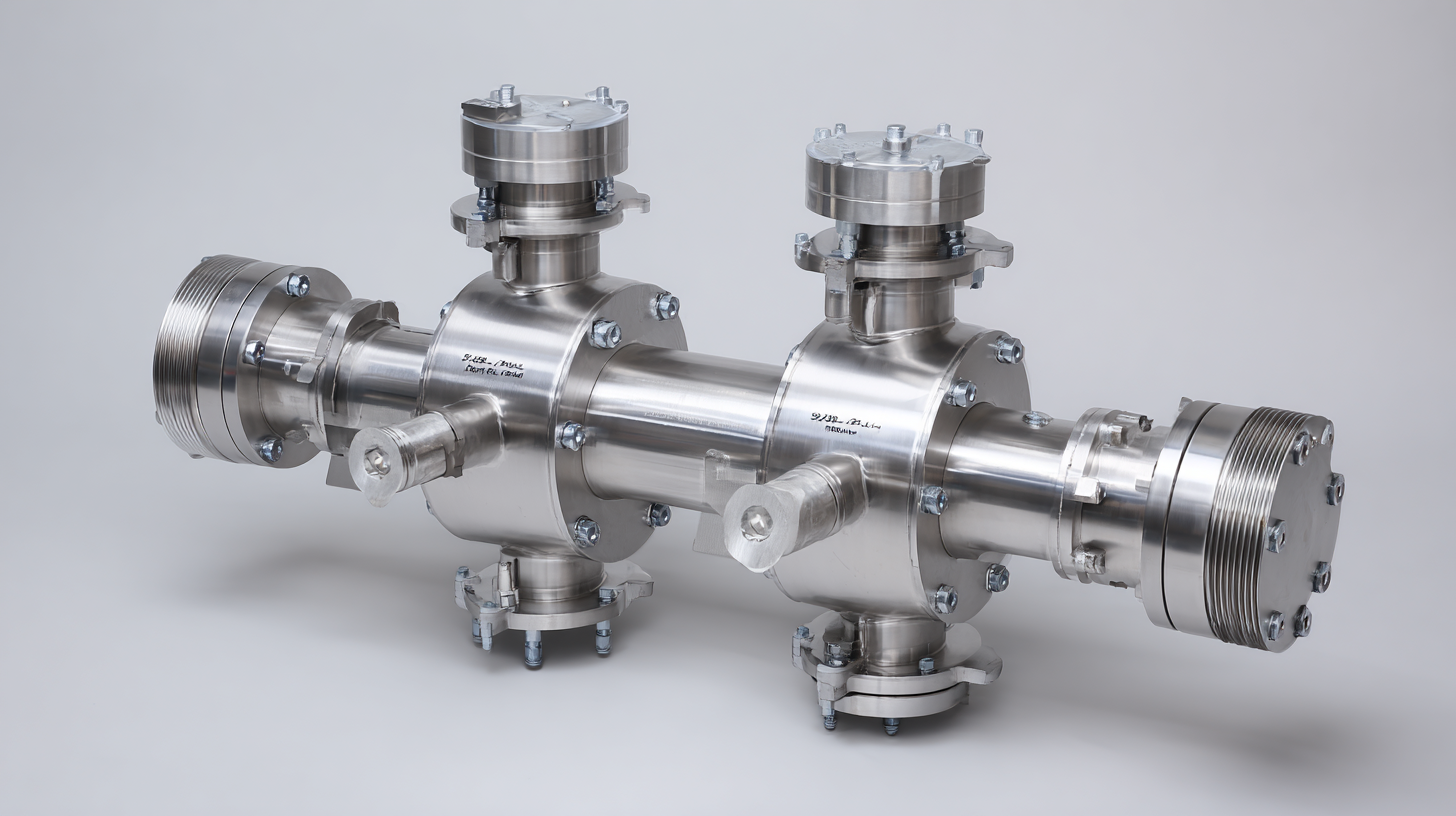

Another advantage of split body ball valves is their robust construction, which ensures high durability and resistance to harsh operating conditions. Constructed from high-quality materials, these valves can withstand extreme pressures and temperatures, making them suitable for various industrial settings, including chemical processing and oil and gas industries. Their ability to provide tight sealing and minimize leakage also aligns with modern demands for sustainability and efficiency in industrial operations, contributing to lower environmental impact and improved safety standards.

Split body ball valves are increasingly favored in industrial applications due to their unique design and operational benefits. One of the primary advantages of these valves is their ease of maintenance. According to a report by Research and Markets, the global market for valves is expected to grow at a CAGR of 5.2% from 2021 to 2026, driven by the increasing need for efficient process control in industries like oil and gas, chemical manufacturing, and water treatment. The split body design allows for easy disassembly and inspection, reducing downtime and maintenance costs, which aligns with the industry’s push for reliability and efficiency.

Furthermore, split body ball valves provide superior performance in terms of sealing capabilities. A study by the Valve Manufacturers Association indicates that leakage rates in split body designs can be as low as 0.01%, making them ideal for applications requiring stringent safety and environmental standards. Their robust construction can handle high pressures and temperatures, making them suitable for harsh environments. This makes split body ball valves not only a practical choice but also an essential component in achieving operational excellence in modern industrial processes.

Split body ball valves are increasingly recognized for their superior performance in industrial applications, especially when compared to traditional ball valves. One significant advantage of split body ball valves is their ease of maintenance and repair. Unlike traditional designs, which often require complete disassembly, split body valves facilitate quicker servicing, minimizing downtime and operational disruptions. This feature is critical for industries that rely on continuous processes and cannot afford lengthy maintenance procedures.

According to a recent market growth forecast report, the global forged steel split body ball valve market is projected to expand significantly from 2025 to 2031, reflecting a growing recognition of their benefits. The report highlights that the adoption of split body ball valves is driven by their enhanced sealing effectiveness and reliability, making them ideal for high-pressure applications in oil and gas, chemical processing, and water treatment sectors. The comparative resilience of split body designs under various operating conditions further positions them as a preferable choice for industries emphasizing safety and efficiency in their operations.

Split body ball valves are increasingly being utilized across various industries due to their unique advantages in maintaining flow control while ensuring ease of maintenance and durability. In the oil and gas sector, these valves offer exceptional reliability, handling high-pressure and high-temperature conditions with ease. Their design allows for quick servicing and replacement of internal components without the need to remove the entire valve from the pipeline, minimizing downtime and operational disruptions.

In the water treatment industry, split body ball valves play a crucial role in managing the flow of liquids and ensuring efficient system operations. Their tight sealing capabilities prevent leaks, which is vital for protecting sensitive ecosystems and maintaining water quality. Additionally, in the pharmaceutical and food processing industries, hygiene is paramount; split body ball valves are manufactured with smooth internal surfaces that eliminate dead zones, making them easy to clean and sanitize while adhering to strict industry regulations. This versatility across diverse applications underscores the growing importance of split body ball valves in modern industrial processes.

| Industry | Key Advantages | Common Applications | Temperature Range | Pressure Rating |

|---|---|---|---|---|

| Oil & Gas | Reduced Leakage, Higher Durability | Pipeline Isolation, Flow Regulation | -30°C to 200°C | Up to 600 psi |

| Water Treatment | Corrosion Resistance, Ease of Maintenance | Flow Control, Water Distribution | 0°C to 70°C | Up to 150 psi |

| Pharmaceutical | Hygienic Design, Easy Cleanability | Process Isolation, Sterile Applications | -10°C to 80°C | Up to 100 psi |

| Chemical Processing | Wide Chemical Compatibility | Reactor Isolation, Transfer Lines | -20°C to 150°C | Up to 300 psi |

Split body ball valves are increasingly preferred in industrial applications due to their superior maintenance capabilities. According to a report by the Valve Manufacturers Association, over 30% of valve failures in industrial settings are attributed to improper maintenance practices. The split body design allows for easier disassembly and reassembly, facilitating quicker inspections and repairs while minimizing downtime. This is particularly beneficial in industries where unexpected outages can significantly impact operational efficiency.

Regular maintenance of split body ball valves can prolong their lifespan and enhance reliability. A study published in the Journal of Industrial Valves indicates that routine checks and timely replacement of seals and gaskets can reduce leakage incidents by up to 40%. Additionally, given that split body ball valves often allow for in-line servicing, technicians can perform routine maintenance without removing the valve from the pipeline, further reducing costs associated with valve replacement and system downtime.

Adopting these maintenance practices not only optimizes performance but also contributes to overall safety in the industrial environment.