-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

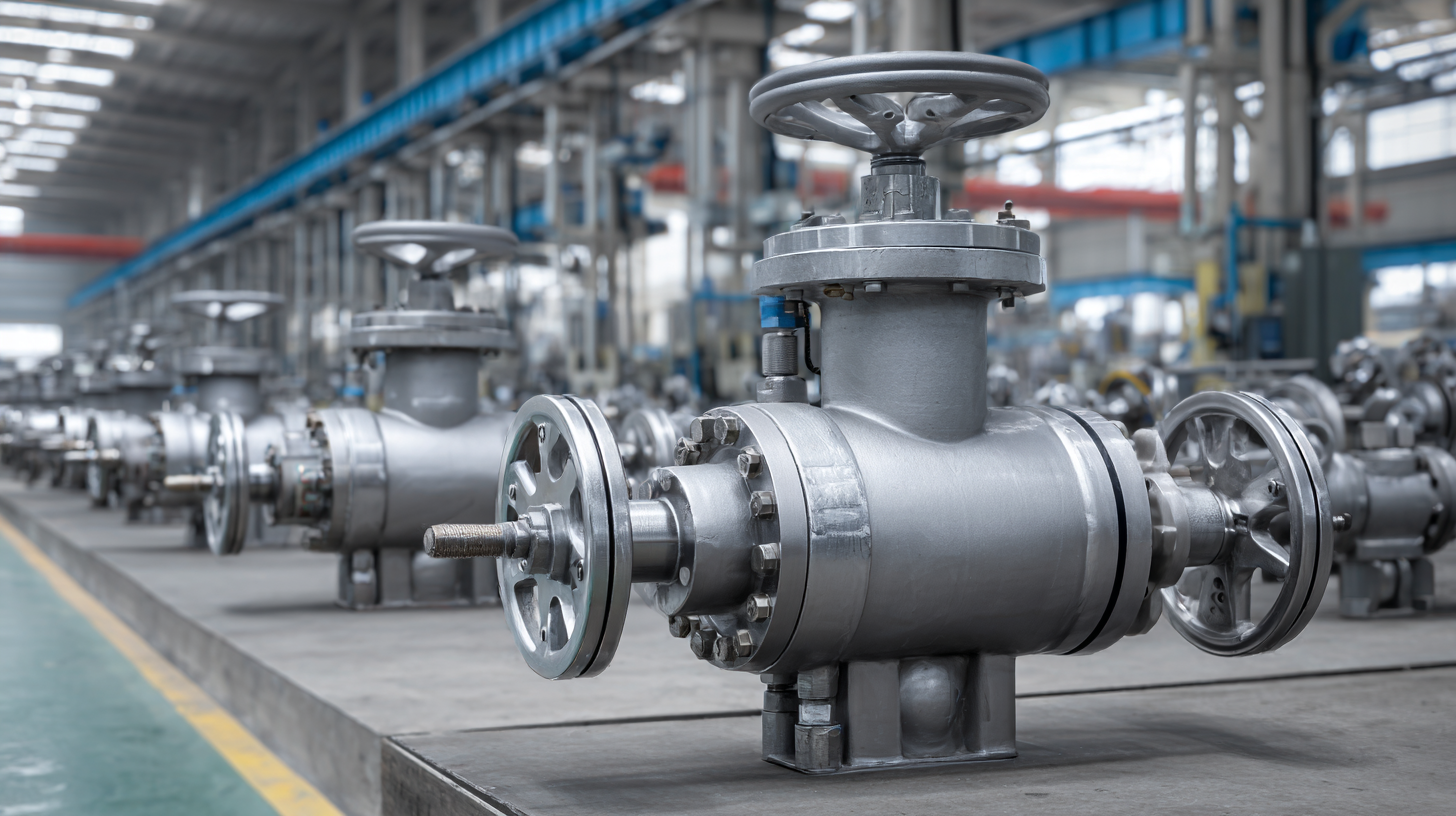

In the ever-evolving landscape of industrial applications, Stainless Ball Valves have emerged as pivotal components in fluid control systems, primarily due to their durability and reliability. According to a recent report by Research and Markets, the global stainless steel valves market is projected to reach USD 16.6 billion by 2025, growing at a CAGR of 5.3%. This growth is largely driven by the increasing demand for high-performance valves in various sectors, including oil and gas, water treatment, and chemical processing. To remain competitive, manufacturers must understand the standards that govern the production and performance of stainless ball valves, ensuring they meet international quality benchmarks. In this blog, we will explore the top strategies for optimizing the design, material selection, and testing processes involved in producing the best stainless ball valves in global markets.

The quality of stainless ball valves is intrinsically linked to their material composition, which plays a crucial role in their performance and longevity in various industrial applications. High-quality stainless steel, such as 316 or 304 grades, is often preferred due to its excellent resistance to corrosion and high temperatures. According to a report by the International Stainless Steel Forum (ISSF), stainless steel usage in the global valve industry has consistently risen, attributed to its durability and strength, which are essential for maintaining operational efficiency in harsh environments.

Moreover, the ASTM A351 standard provides stringent guidelines for the chemical composition and mechanical properties of stainless steel used in ball valves. This ensures that manufacturers produce valves that meet required specifications for tensile strength, yield strength, and corrosion resistance. A recent market analysis by Research and Markets revealed that products meeting these international standards not only reduce maintenance costs but also significantly enhance the safety and reliability of fluid control systems. Therefore, understanding material composition is vital for end-users seeking to select the best stainless ball valves that can withstand demanding industrial conditions.

When it comes to stainless ball valves, understanding key industry standards is essential for both manufacturers and buyers. Standards such as ASTM A351 and API 608 not only dictate the material properties and manufacturing processes but also ensure performance and safety. These specifications guide the creation of high-quality valves that can withstand pressure and temperature fluctuations, making them suitable for a variety of applications in sectors like oil & gas, water treatment, and food processing.

Tip: Always look for compliance with recognized standards when selecting stainless ball valves. Certified products typically indicate reliability and quality assurance, which can result in cost savings in the long run due to reduced maintenance and downtime.

Moreover, the valve's design often adheres to international standards like ISO 17292, which evaluates the functional and safety requirements of valves. This not only standardizes quality across different regions but also facilitates interoperability, making it easier for global companies to source and use these critical components.

Tip: Consider the valve's end connections and operating parameters defined by standards, as they affect compatibility with existing systems and overall operational efficiency.

When evaluating the best stainless ball valves in global markets, understanding performance metrics like pressure ratings and flow coefficients is crucial. Pressure ratings indicate the maximum allowable pressure that a valve can withstand without failure. They are typically expressed in terms of psi (pounds per square inch) or bar, making it essential for engineers and buyers to select valves that meet or exceed the operational requirements of their systems. Factors such as temperature variations and media type must also be taken into consideration, as they can affect a valve's performance under pressure.

Flow coefficients, or Cv values, measure the flow capacity of a valve at a given pressure drop, helping to determine how well a valve can control fluid flow. A higher Cv value suggests a more efficient valve, as it can pass a greater volume of fluid for a given pressure drop. This metric is particularly important in applications where maintaining optimal flow rates is essential. By understanding and comparing these performance metrics, consumers can make informed decisions when selecting stainless ball valves that guarantee reliability and efficiency in their respective applications.

The demand for stainless ball valves has seen a significant surge across various industries, driven by their superior durability and resistance to corrosion. According to a recent report by MarketsandMarkets, the global stainless steel valve market is projected to reach USD 22.53 billion by 2026, growing at a CAGR of 5.3% from 2021. Industries such as oil and gas, water and wastewater, and chemical processing are leading this growth, as stainless ball valves offer reliable performance under extreme conditions.

In the oil and gas sector, the increasing need for efficient flow control solutions for both upstream and downstream processes has accelerated the adoption of stainless ball valves. Meanwhile, the water and wastewater treatment industry is gravitating towards these valves to enhance system longevity and reduce maintenance costs. As per Allied Market Research, the wastewater treatment market alone is expected to reach USD 740.8 billion by 2027, indicating a strong future demand for stainless ball valves.

Tip: When selecting stainless ball valves, consider factors such as pressure rating, temperature tolerance, and compatibility with the fluids in your system. Ensuring proper specifications can significantly extend the service life of the valves. Always consult with manufacturers to understand the specific requirements for your application to avoid costly downtimes.

In the competitive landscape of the stainless ball valve market, understanding the strengths and capabilities of leading manufacturers is crucial for informed decision-making. A comparative analysis reveals that companies like Swagelok, Parker Hannifin, and Val-Matic stand out not only for their innovative designs but also for their adherence to international standards such as ASTM and ANSI. These manufacturers employ rigorous testing and quality control measures to ensure their products meet industry specifications, providing customers with reliable solutions for various applications.

Additionally, it is essential to consider the technological advancements and material innovations that different manufacturers bring to the table. For instance, some companies are focusing on enhancing corrosion resistance and durability through advanced stainless steel formulations, while others are investing in automated production processes to improve efficiency. By comparing these attributes across leading players, buyers can better navigate the intricate dynamics of the market, ultimately selecting the right stainless ball valve that aligns with their operational needs and quality expectations.