-

Home

-

Products

-

About Us

-

Application Cases

-

CLIENT & FACTORY

-

Test

-

News

-

Contact Us

Leave Your Message

Choosing the right equipment for high-temperature applications is crucial for ensuring efficiency and safety in various industrial processes. One essential component in this context is the High Temperature Ball Valve, which plays a pivotal role in regulating the flow of fluids at elevated temperatures. This comprehensive guide aims to provide you with all the necessary information to make an informed decision when selecting the best High Temperature Ball Valve for your specific needs.

From understanding the critical features and materials used to recognizing the importance of proper installation and maintenance, this guide will equip you with the knowledge to choose a valve that not only meets your operational requirements but also enhances the overall productivity of your system. Whether you are dealing with aggressive chemicals, high-pressure conditions, or extreme temperatures, our expert insights will help you navigate through the myriad of options available, ensuring that you find the perfect fit for your application.

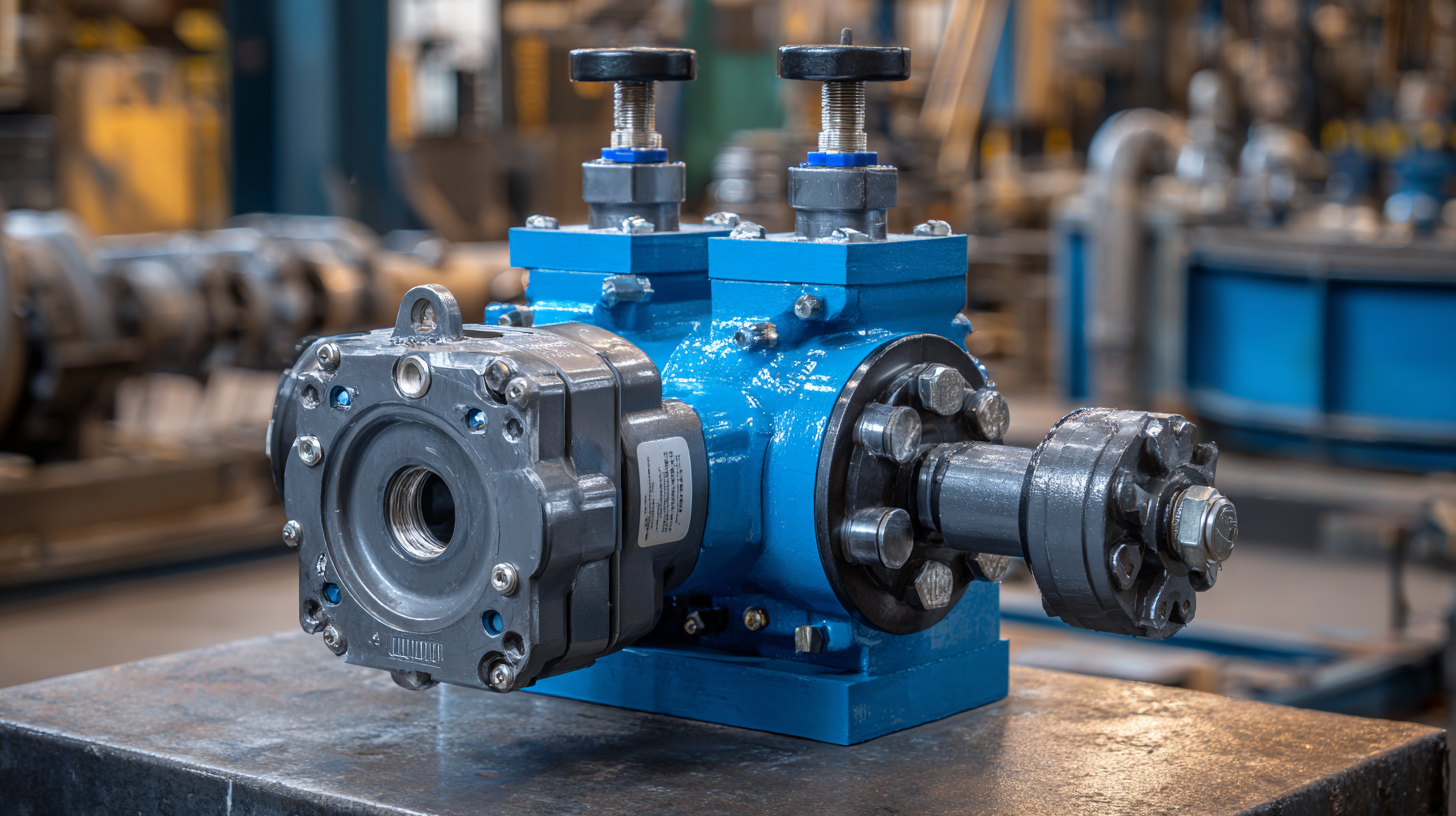

When selecting a high temperature ball valve, it’s essential to understand the key features and specifications that determine its performance and reliability. High temperature ball valves are specifically designed to withstand extreme thermal environments, making them vital for industries such as oil and gas, power generation, and chemical processing. The materials used in their construction, such as stainless steel or special alloys, play a crucial role in their ability to resist thermal expansion and corrosion caused by high temperatures.

Another critical aspect to consider is the valve design, which can significantly influence efficiency and operational safety. Features like a blowout-proof stem and fire-safe designs ensure that the valve not only performs effectively under high temperatures but also provides added security in case of an emergency. Furthermore, the valve's pressure rating and size must align with specific application requirements to ensure optimal functionality. Understanding these elements will aid in making an informed decision when selecting the best high temperature ball valve for your distinct needs.

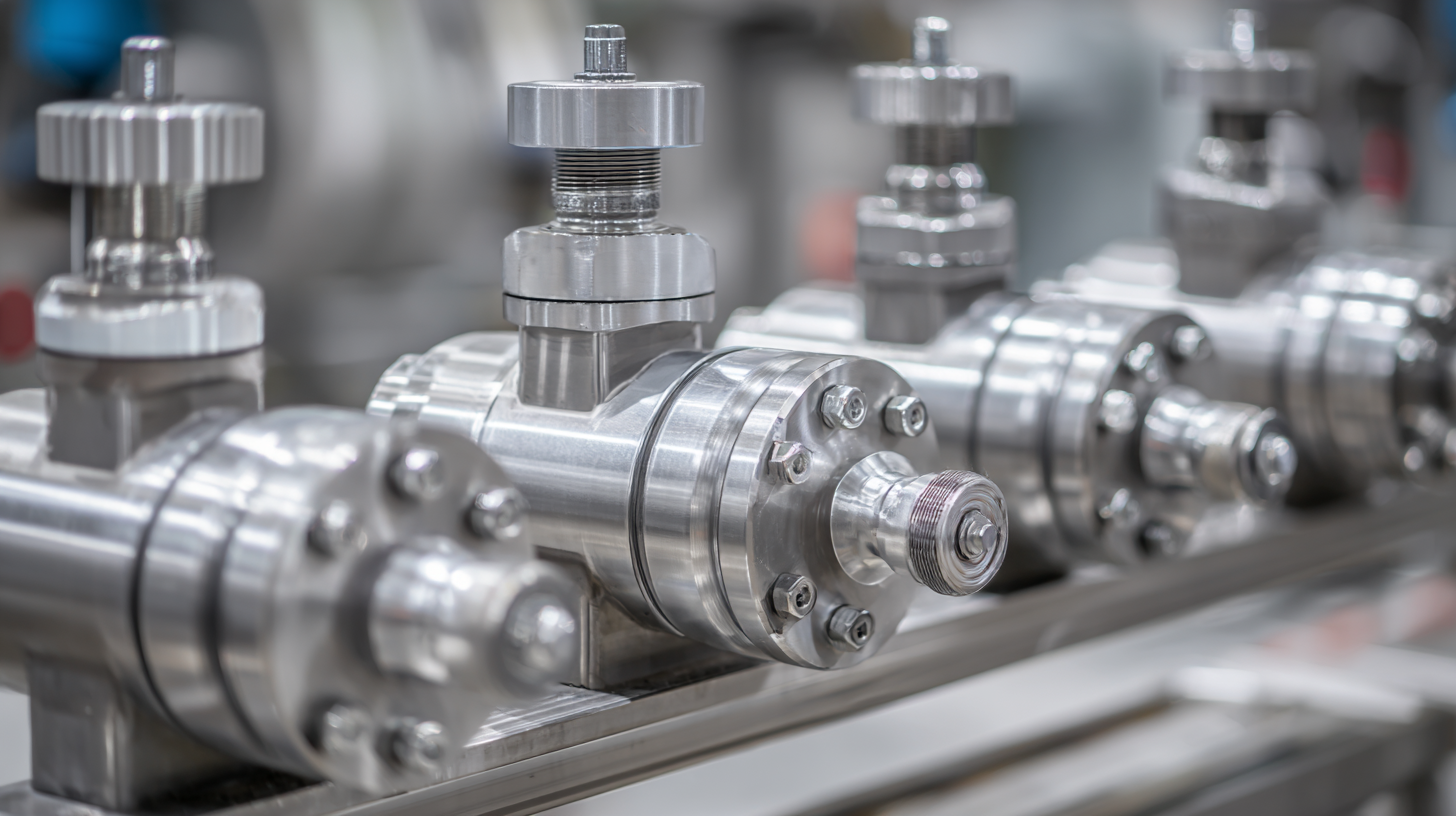

When dealing with high temperature ball valves in industrial applications, several common issues can arise, significantly impacting performance and safety. One significant concern is thermal expansion, which can lead to misalignment and leakage. When materials expand under high temperatures, valves may become stiff or fail to seat correctly. It's crucial to assess the materials used in the valve's construction to ensure they can withstand the specific temperature fluctuations of your application.

Tip: Always opt for high-quality materials that are compatible with the temperature ranges in your operation. Look for valves designed specifically for high-temperature applications, often made from special alloys or reinforced plastics.

Another issue to consider is the potential for fouling or scaling inside the valve, particularly in processes involving steam or corrosive substances. These build-ups can restrict flow and lead to increased wear over time. Regular maintenance and inspections are essential to detect these issues early.

Tip: Implement a routine maintenance schedule that includes inspection for scaling and fouling, as well as periodic cleaning processes. This not only extends the life of your ball valves but also ensures they operate efficiently.

When selecting a high temperature ball valve, the choice of materials and design considerations is critical to ensure optimal performance and longevity under extreme conditions. High temperature applications typically require robust materials that can withstand elevated pressures and temperatures without compromising integrity. Common materials include various grades of stainless steel, specialty alloys, and high-performance polymers that can resist thermal degradation and oxidation. It’s essential to evaluate the compatibility of these materials with the specific fluids being handled, as improper material selection can lead to failure.

Moreover, the design of the ball valve itself plays a significant role in its efficiency and reliability. Features such as the valve’s seat design, sealing mechanisms, and actuator compatibility must be meticulously considered to ensure seamless operation. Advanced design techniques, including computational fluid dynamics, can optimize the flow characteristics and reduce turbulence, enhancing overall system performance. Additionally, understanding the installation and operational environment is crucial, as factors like thermal expansion and space constraints will affect the choice of valve design. By carefully analyzing these materials and design considerations, users can select a high temperature ball valve that meets their specific requirements and minimizes future maintenance challenges.

This chart illustrates the common materials used in high temperature ball valves along with their maximum temperature ratings. This data helps in selecting the right valve according to temperature requirements.

When it comes to high temperature ball valves, troubleshooting common issues can save you time and costly downtime. One frequent problem is leakage, often caused by worn seals or improper installation. Regularly check the sealing surfaces and ensure they are clean and properly aligned before assembly. A good practice is to inspect the valve after significant temperature changes or operating conditions to catch any potential leaks early.

Another issue might arise from the valve not opening or closing properly. This can happen due to debris accumulation or thermal expansion affecting the valve’s operability. To address this, implement a routine maintenance schedule that includes cleaning the valve and checking for any obstructions. If the valve still doesn’t function correctly, consider whether the actuator is properly calibrated.

**Tips:** Always select ball valves made from materials specifically designed for high temperature applications, as this can enhance durability and performance. Additionally, utilize thermal insulation on piping and valves to minimize temperature fluctuations and stress on the valve components. These proactive measures can significantly extend the lifespan of your high temperature ball valves.

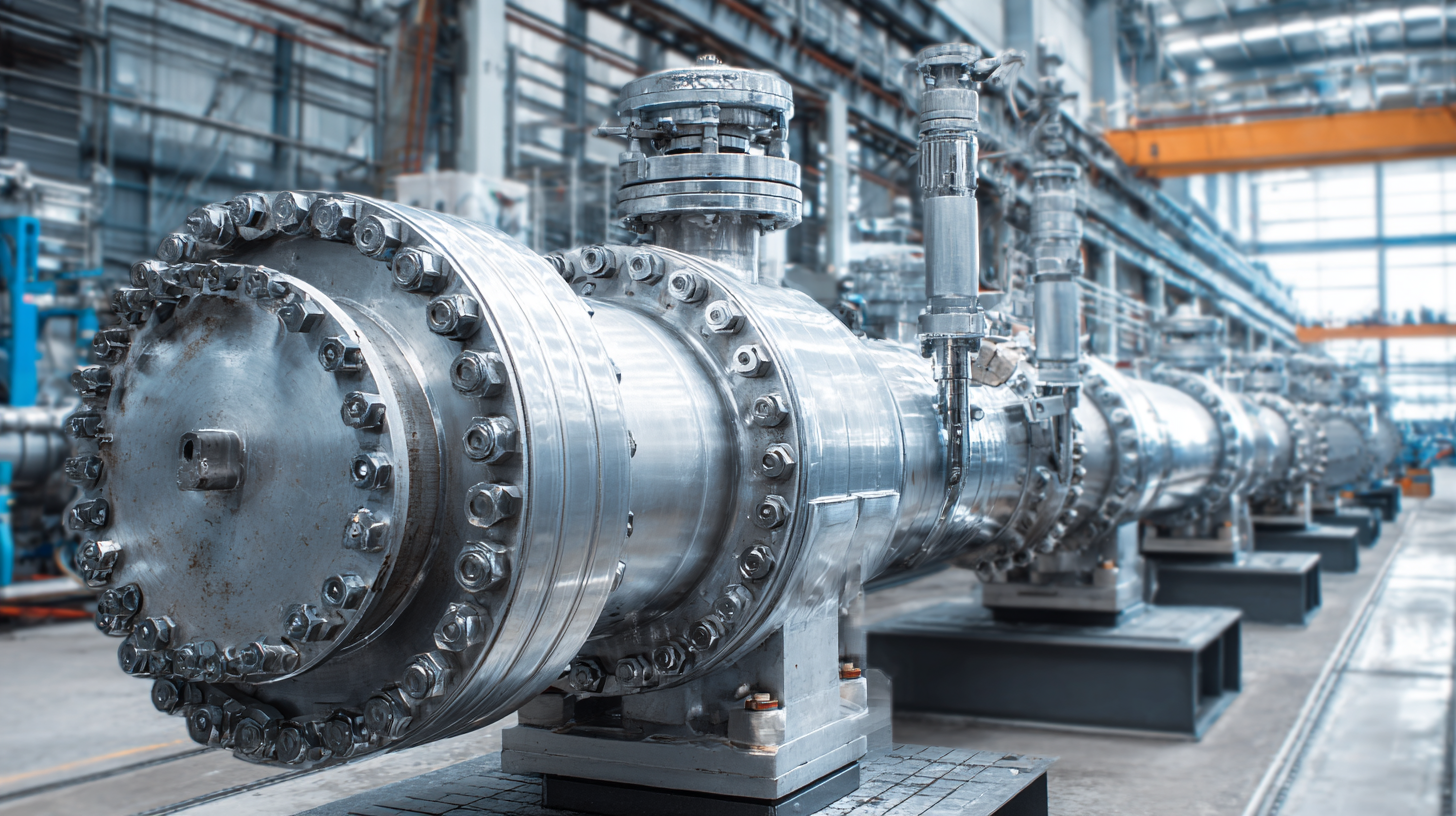

When it comes to high temperature ball valve systems, regular maintenance is crucial to prevent failures that can lead to costly downtime and safety hazards. According to a report by the Fluid Sealing Association, nearly 80% of valve failures can be attributed to improper maintenance practices. To mitigate such risks, operators should adhere to a scheduled inspection routine that includes checking for signs of wear, corrosion, and damage, particularly in critical applications involving steam, thermal oil, or other high temperature media.

Additionally, lubricating the valve seats and stems with high-temperature-resistant greases is essential for maintaining smooth operation and preventing seizing, which can result from thermal expansion or excessive heat. The American Society of Mechanical Engineers recommends that specific high-temperature lubricants be used legally and efficiently within the operational limits of the valve material, significantly extending the lifespan of the valve components. Ensuring proper thermal insulation around piping and connections can further enhance the performance of these systems by minimizing heat loss and protecting the integrity of the valves, thus creating a reliable and efficient operational environment.

| Dimension | Material | Temperature Range (°C) | Pressure Rating (PSI) | Maintenance Frequency (Months) |

|---|---|---|---|---|

| 1/2" | Stainless Steel | -20 to 120 | 1500 | 6 |

| 3/4" | Carbon Steel | -40 to 150 | 1300 | 8 |

| 1" | AFR Material | -10 to 180 | 1200 | 12 |

| 1-1/2" | Bronze | -20 to 200 | 1000 | 10 |

| 2" | PVC | 0 to 60 | 600 | Electrical Inspection Annually |